TECHNICAL ARTICLE

TECHNICAL ARTICLE

Unveil the secret to perfect soy milk with Palsgaard's emulsifiers and stabilisers. Elevate your soy milk production, enhancing taste and extending shelf-life. Our integrated systems, like Palsgaard® RecMilk 122 and Palsgaard® ChoMilk 173, craft creamy, stable soy milk—be it the Western style with 3% protein or the Asian style with lower protein and added sugar. With mono- and diglycerides ensuring a velvety texture and carrageenan preventing sedimentation, your soy milk stays enticingly consistent throughout its life. Palsgaard empowers your soy milk creation, delivering quality that captivates.

Soybeans have been used for human nutrition for more than 5000 years and soy milk has been known in China for at least 2000 years. Today, soybeans are an important source of protein and oil in human nutrition, especially in Asia. In other parts of the world, soy-based foods are consumed merely due to their healthy image. Several health benefits have been found in soy proteins e.g.:

Within soy products, an increasing consumption around the world is seen in soy products resembling dairy products like for instance milk, yoghurt and ice cream. These products also make up a valuable alternative for people allergic to cow's milk.

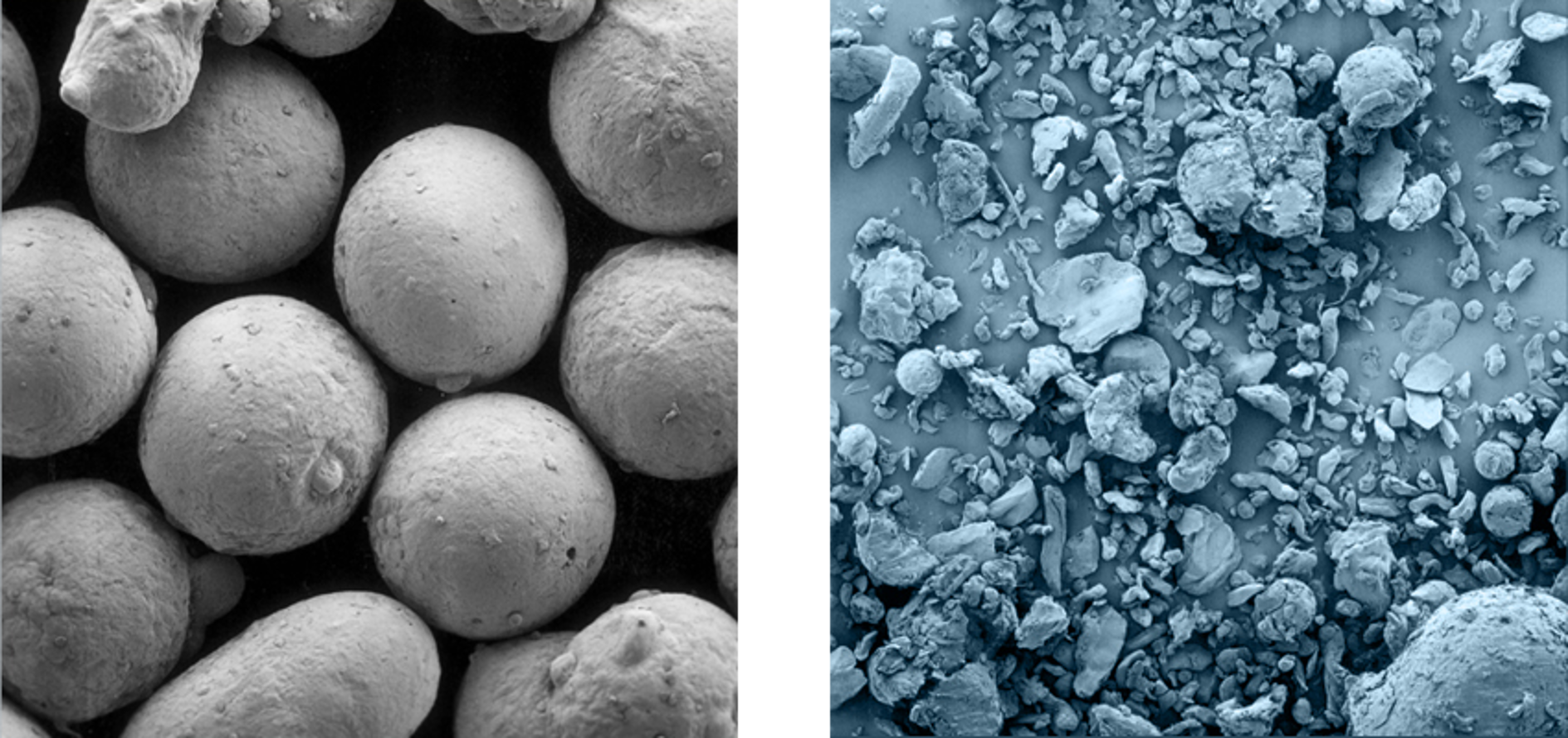

The cultivated soybean Glycine max is a member of the Leguminosae family and is related to clover and peas. It’s an annual and non-frost-tolerant plant. The seeds are contained in pods. Depending on the variety the seed size is 3600 – 8000 seeds/kg. The mature bean normally has a light yellow colour and has a moisture content of 13-14%. If the water content is higher than 13.5% the beans must be dried prior to storage; otherwise, enzyme activity is leading to oxidation of the fats.

Soybeans have approximately 40% protein, 35% carbohydrates and 20% oil calculated on the dry matter. Further, it is rich in vitamins and minerals. Soybeans contain all the essential amino acids making it a valuable protein source in human nutrition.

Soy milk is a water extract from whole soybeans. It is an emulsion containing water-soluble proteins, carbohydrates and oil droplets. Soy milk was traditionally produced in small shops where the soybeans were soaked, ground, filtered and cooked. These products have a short shelf-life. However, today’s consumers, and the modern lifestyle, request products with a longer shelf-life and which remain safe and stable during the complete storage period.

For the production of such soy milks and beverages, the utilization of the UHT technology is obvious. Hereby a shelf-life from several months and up to a year can be obtained, depending on the composition of the product. Further, the right choice of emulsifiers and stabilisers is necessary for ensuring a homogeneous product without creaming and sedimentation during the entire shelf-life.

The first step in the production of soy milk, or for that matter yoghurt, desserts and ice cream from whole soybeans is the production of soy milk base. During this process, the proteins, soluble carbohydrates and oils are separated from the fibre material, the so-called okara. This base is then further formulated and processed into the desired soy product.

The soy base can be produced in several ways by applying or omitting various processing steps. The choice of processing determines the chemical, nutritional as well as sensory properties of the soy base; such as the content of oligosaccharides causing flatulence, trypsin inhibitors influencing protein digestion and off-flavour components. A typical soy milk base has 45% protein, 20% oil, 17% carbohydrates and 8% ash calculated on the dry matter. Below the steps in soy base production are described:

The starting point for soy base production can be either whole or dehulled soybeans. By dehulling, some of the bitter-tasting components are removed and further, the level of oligosaccharides is decreased, resulting in a better digestion of the final soy product. Further alkali blanching improves the inactivation of the trypsin inhibitors. From a processing point of view, alkali blanching is an advantage as it depresses foam formation during production.

Hydration of the beans prior to grinding improves the grinding efficiency and takes place during soaking or continuous blanching. Soaking promotes the formation of a beany flavour in the soy product, which is desired in some parts of the world, for instance in many of Asian countries. During blanching lipoxidases and trypsin inhibitors are inactivated. The presence of lipoxidases in the product results in the development of a beany flavour.

The grinding results in a colloid solution of the soybeans in water, also called soy slurry. The concentration of the slurry and hence the protein concentration in the soy base is determined by the bean-to-water ratio at the inlet to the grinders. The soy base containing proteins, soluble carbohydrates and oils now have to be separated from the fibre material, okara. This is done by means of a decanter centrifuge. The efficiency of the decanter is important for the yield as well as for the quality of the soy milk. For optimized yield, the moisture content in the okara should be low. Likewise, the amount of sediment in the slurry should be low to avoid chalkiness caused by insoluble particles in the final soy product. An efficient decanter removes up to 99.8% of the sedimentable solids.

For removal of undesirable volatile off-flavours giving beany flavour, the soy base is exposed to direct steam infusion heating to 140°C followed by flash cooling and vacuum deodorisation. This process not only removes the volatile off-flavours, it also inactivates the trypsin inhibitors and any enzymes not yet inactivated and which might have led to the formation of off-flavour during storage. Further, it removes air from the product which otherwise could have caused oxidation in the product.

The soy base is now ready for standardization to the desired protein content and composition by adding water and other ingredients and further processing into for instance soy milk, soy drink, yoghurt and ice cream.

The first step in the production of soy milk is the standardization and formulation of the soy milk base. Basically, two different types of soy milk are produced:

The Western-style resembles dairy milk when looking at the protein content, as soy milk is seen as an alternative to cow’s milk. The product typically contains approx. 3% protein, 2% oil and 2% carbohydrates. It may be fortified with e.g. calcium and vitamins. It is used for drinking as well as for cooking, which is challenging the technological properties of the product. Further, flavoured versions such as chocolate and vanilla soy milk are often seen.

The Asian-style soy milk is more of a beverage with lower protein content, down to 1% and a higher sugar level; 5-10% added sugar is quite common. As for the Western style, the beverages may be fortified as well as flavoured.

Nowadays, a large part of the industrially produced soy milk is produced by means of the UHT process and aseptic filling, thereby obtaining a long shelf-life at room temperature. This puts a great demand on the stability of the product as a homogeneous product throughout the entire shelf-life is necessary for the consumer’s acceptance of the product. Direct as well as indirect UHT systems may be applied. From a stability as well as from a sensory point of view direct systems are preferred. Direct systems result in fewer chemical changes in the product due to a lower total heat load and extraction of oxygen from the product in the vacuum chamber. The indirect system is, however, often preferred due to lower investment and running costs.

Whichever UHT system is used, the application of emulsifiers and stabilisers in soy milk and soy milk beverages is necessary. The products are emulsions of oil in water and for ensuring optimal emulsion stability, i.e. reducing creaming, during the entire shelf-life, not only proper homogenization but also the addition of selected emulsifiers and stabilisers is necessary. Further, the stabilisers improve the stability of the proteins minimizing sedimentation during the storage of the soy product.

The functionality of the emulsifiers and stabilisers is described below.

Mono- and diglycerides of fatty acids are commonly used as emulsifiers in liquid soy products. Mono and diglycerides are emulsifiers produced by the reaction of edible vegetable fats and oils and glycerol. The result is a molecule with a hydrophilic and a lipophilic part and consequently, it will locate at the interface between the fat/protein and water. This happens during homogenization of the soy milk. The mono- and diglycerides complex with the soy proteins, and make the fat globule membrane more resistant towards coalescence. Hence, they reduce the creaming or fat separation in the product. However, they do also reduce the net charge of the fat globule and thereby increase the flocculation of the fat globules forming a three-dimensional network and improving the creaminess in the drink.

Carrageenan is by far the most commonly used stabiliser in soy milk. Carrageenan is extracted from seaweed. The carrageenan forms a helix with negatively charged sulphate groups turning outwards. This helix interacts to some extent with the protein particles preventing sedimentation in the product. In a chocolate drink, a 3-dimensional network formed by the carrageenan keeps the cocoa particles in suspension. Combined with mono- and diglycerides carrageenan ensures a stable and homogeneous soy milk during the entire shelf-life.

For use in soy milk and soy drinks, Palsgaard has developed the integrated emulsifier and stabiliser system Palsgaard® RecMilk 122 which includes mono- and diglycerides and carrageenan as the main stabiliser. If the soy milk contains particles, for instance in soy chocolate milk and soy chocolate drink, which have to be dispersed Palsgaard® ChoMilk 173 has to be used. Palsgaard® ChoMilk 173 also includes mono- and diglycerides and carrageenan, however, the composition is adjusted to stabilise the particles in the drink.

Take advantage of Palsgaard's unique insights into plant-based consumer trends and specific local requirements, and choose Palsgaard for your next innovation project. Our experienced food

technologists are experts at solving challenges within sensory requirements, shelf-life stability, sedimentation control, water retention and emulsion stability. Not to mention equipment limitations or ingredient availability – and they’re happy to share their know-how.

With application centres in Denmark, Mexico, Singapore, China and Türkiye, help is never far away.

As part of our service, we’re happy to share our series of start-up recipes for vegan drinks, plant-based tea lattes, milk-alternative beverages and coffee creamers and plant-based yoghurts. All were tested on a variety of plant-bases ranging from almonds, nuts, oats, peas, coconut, rice, soybeans, sesame and more.

TECHNICAL ARTICLE

TECHNICAL ARTICLE

TECHNICAL ARTICLE

TECHNICAL ARTICLE

CONSUMER SURVEY