TROUBLESHOOTING BY PALSGAARD

TECHNICAL ARTICLE

There are more ways than ever to meet the growing consumer demand for no-added-sugar ice cream, but it can be a challenging process. Here Claus Prior Hansen, Application Manager, Ice Cream & Dairy, explains why replacing sugar is a complicated balancing act between getting the right texture, sweetness and eating sensation of the no-added-sugar ice cream:

"When you take out sugar, you’re taking out a major part of the recipe. As well as providing sweetness, it affects freezing point and solid content, so really what you have to do is to replace one ingredient with three or more ingredients. You then have to balance the recipe according to the ingredients you’re choosing, and there are a lot of different combinations you can use. It can feel like a complicated game sometimes."

“In the past, the market for no-added-sugar ice cream was very small, but it’s definitely growing,” Claus says. “Partly that’s because of demand for calorie-reduced products generally. Along with low-fat, no-added-sugar helps you appeal to health-conscious consumers. The other big factor is the growing population of people with diabetes. Of course, they still want great-tasting products that they can eat without having to worry. Producers have to be able to offer something to everyone, so as with plant-based options, they have to have no-added-sugar products in their portfolios.”

He also points out that ice cream producers now have more choice of ingredients than ever. “It used to be that there were only one or two alternatives to sugar in ice cream. Now there’s a wide range of sugar alcohols and sweeteners, so it’s getting easier to create products that taste and feel like traditional ice cream.”

Traditional ice creams commonly contain sugar in two forms – sucrose and glucose syrup. Together, they typically account for up to half of the total solids in the ice cream, and replacing them can be difficult because of the important functional roles they perform.

“When you take out sugar, you’re taking out a major part of the recipe,” Claus explains. “As well as providing sweetness, it affects freezing point and solid content, so really what you have to do is to replace one Ingredient with three or more ingredients. You then have to balance the recipe according to the ingredients you’re choosing, and there are a lot of different combinations you can use. It can feel like a complicated game sometimes.”

The first factor that has to be addressed in the process isn’t sweetness but the freezing point. “When you add water-soluble ingredients like sugar to water as in an ice cream mix, you lower the freezing point,” Claus explains. “This is important because it gives you softness and prevents the product from being rock-hard when the consumer is eating it. So if you take out sugar you have to add something that allows you to keep that freezing point depression.”

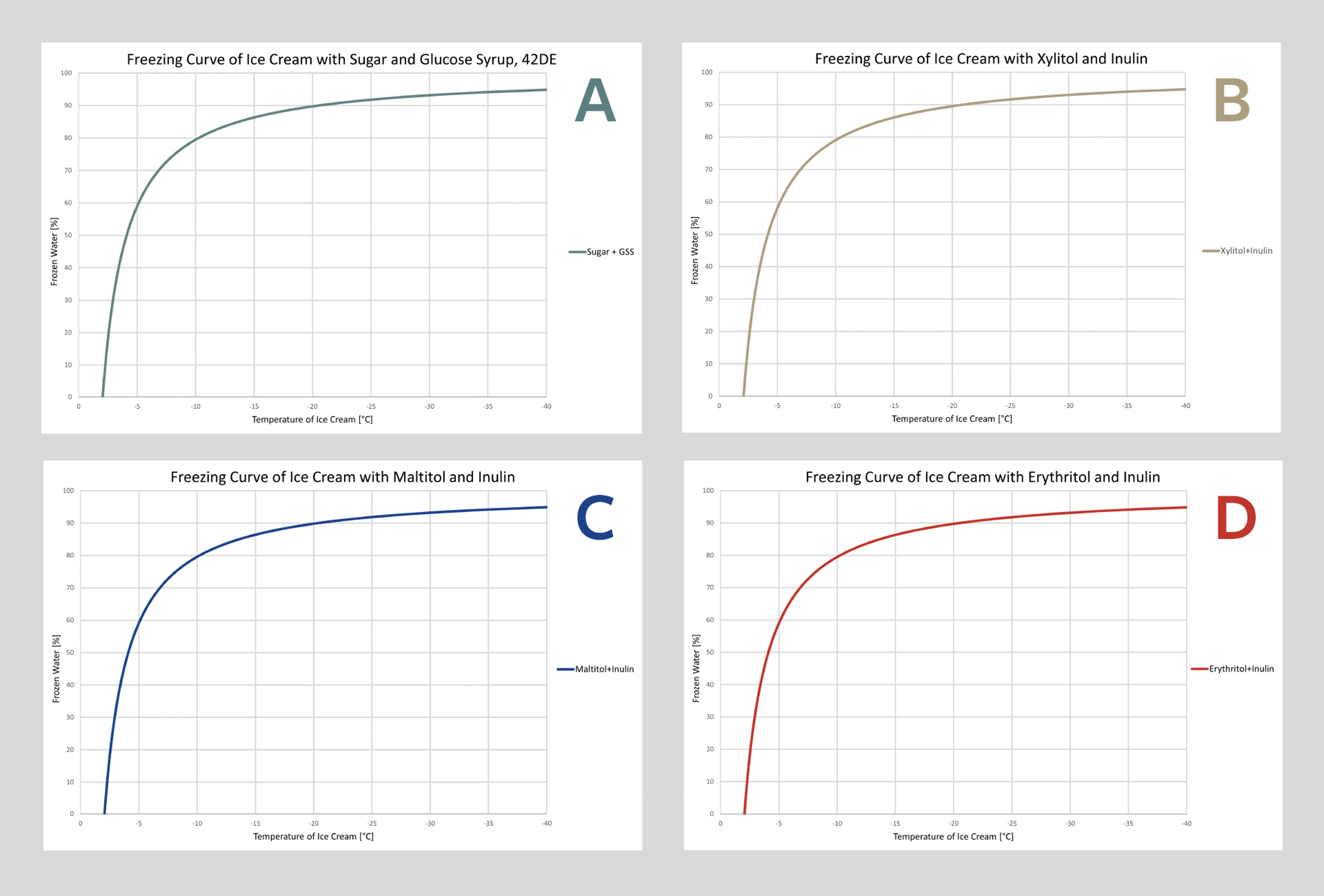

This is commonly achieved by using sugar alcohols such as erythritol, maltitol and xylitol. They can be added in different concentrations to give the right freezing point and freezing curve or profile, with many manufacturers using a combination of two or three. These sugar alcohols are often stronger in the freezing point depression than sugar, and will therefore be used in a lower dosage than the removed sugars, leading to a lack of solids in the recipe.

The next consideration is solid content. “You have to add solids to maintain creaminess and mouthfeel and prevent the product from feeling watery when eaten,” Claus explains. “Bulking agents such as inulin, fibre or polydextrose allow you to increase the solid content without affecting the sweetness or the freezing point depression. Depending on which you choose, you can affect the texture and mouthfeel.”

Adding high-intensity sweeteners is the final step of the process. “Of course, it’s a dessert product so it’s expected to be sweet,” Claus says. Again, a range of options are available: “Aspartame used to be the most commonly used high-intensity sweetener but now there’s sucralose and plant-based options like stevia glycosides. They’re used at a very low dosage, so they don’t affect the freezing point, the solid content or the texture, allowing you to add them as the last ingredient in the substitution of sugar.”

The range of different ingredient options available to manufacturers means they can tailor their recipes based on market needs. “Different sugar replacers can deliver different benefits in different regions,” Claus says. “The combination that’s right for you will depend on where you are in the world, and on local tastes and rules. For example, consumers in different areas want different levels of sweetness and softness. And depending on local regulations, some ingredients might allow you to make a claim like ‘source of fibre.’”

However, there can be drawbacks too: “Sugar alcohols each have an E-number, so using several isn’t a great option if you want a leaner label. The other fact to be aware of is that sugar alcohols can have a slight laxative effect, so if people eat a lot, they can have digestive problems.”

To help ice cream manufacturers meet a range of market needs Claus’ team has created three new recipe concepts for no-added-sugar ice cream. Each uses a different combination of sugar alcohols, bulking agents and sweeteners to deliver slightly different properties in terms of texture, mouthfeel and nutritional values while keeping freezing point depression and sweetness the same for all three.

Claus says the main goal was to create recipes that were as similar as possible to an ice cream based on sugar: “We ran a series of trials (see figure 1), and these were the ones that delivered the best quality compared to the reference. We wanted to mimic the freezing qualities of ice cream with sugar as closely as possible, but we also wanted some variety. So, one of the recipes was based on a sugar alcohol, that is close in molecular weight to sugar, as this gives you a freezing curve that’s very similar to the reference. The other two recipes, based on sugar alcohols with a molecular weight much less than sugar, need different quantities of bulking agent to match the freezing curve of the reference."

The process was supported by a nifty tool – a spreadsheet that predicts the freezing curve (the volume of water frozen at different temperatures) of ice cream depending on its ingredients. It also helped Claus to predict factors like sweetness and solid content, although it did have limits. “It’s a very good tool,” he says. “But it’s only the starting point to create the base recipe. We then had to do physical trials to establish parameters like melting point and mouthfeel.”

One thing no-added-sugar recipes have in common with traditional ice cream is the need for emulsifiers and stabilisers, which control qualities like melting resistance and creaminess, as well as improving mouthfeel

The good news is that Palsgaard products work just as well in no-added-sugar recipes. Claus used a standard Palsgaard® emulsifier and stabiliser system that can be used in all types of ice cream but is particularly suited to low-fat recipes. Other options that would have worked well are Palsgaard® ExtruIce or Palsgaard® Mouldice.

Would you like to try our recipes for no-added-sugar ice creams?

Contact us here to order the recipes and samples of our emulsifiers and stabilisers so that you can try out the recipes for yourself.

TROUBLESHOOTING BY PALSGAARD

TECHNICAL ARTICLE

TECHNICAL ARTICLE

TECHNICAL ARTICLE

TECHNICAL ARTICLE

TECHNICAL ARTICLE

TECHNICAL ARTICLE

TECHNICAL ARTICLE