TROUBLESHOOTING BY PALSGAARD

TECHNICAL ARTICLE

Unlock the secret to creating indulgent, high-overrun ice cream that doesn't compromise on quality. Discover expert tips and techniques for achieving the perfect texture and stability in your ice cream production with Palsgaard's latest knowledge and innovation insights.

In this article, Claus Prior Hansen, Application Manager, Ice cream & Dairy, Palsgaard A/S, explores ways to mitigate another factor affecting quality – high overrun.

People have been enjoying ice cream in one form or another for several centuries and it remains one of the world’s most common snacks and desserts. Ice cream is generally consumed as a luxurious treat, but the pleasure of eating it depends on smoothness and creaminess throughout the shelf-life. Of course, recipe and processing parameters determine this to a large extent, but they’re not the only factors affecting the quality of the product experienced by consumers. During transportation and storage, for example, there is a high risk of heat shock and therefore loss of quality.

Ice cream is a complex system of foam, containing a gas (air) dispersed as small bubbles. Within this partially frozen continuous phase, fat is dispersed as an inner phase in an emulsion, in which the milk solids and stabilisers are in a colloidal solution, and sugar and salts form a true solution.

Air is an important component in ice cream, affecting its physical and sensory properties as well as its stability during storage. Overrun refers to the degree of expansion resulting from the amount of air incorporated into the product during the freezing process. Ice cream normally has an overrun of around 100%, meaning that air makes up 50% of its volume. The amount of air incorporated into the mix influences sensory attributes – with less air, the resulting ice cream is dense and heavy and feels colder to eat; with more, the texture is lighter and creamier and feels less cold.

Opting for a high overrun can be a useful strategy for reducing the costs of ice cream production, but its impact on perceived quality has to be considered. Sensory attributes such as creaminess and smoothness, as well as resistance to shrinkage and melting, should not be compromised because they are very closely linked to consumer preferences.

Creaminess, as well as melting resistance, is related to the distribution of air cells – a more uniform air cell distribution results in a creamier and slower melting ice cream. High overrun broadly means that there are more air cells, with a larger total surface area. This means that the walls of the air cells are thinner and weaker, with higher risk of deterioration in quality and stability.

The good news is that by choosing the right emulsifiers and stabilisers it is possible to manufacture an ice cream with high overrun which is still perceived as high-quality. Emulsifiers like mono- and diglycerides are well known for their positive influence in this respect.

Emulsifiers are surface-active ingredients with hydrophilic-lipophilic properties. They place themselves in the interfacial layer between the fat/protein and water and destabilize the membranes of the fat globules formed during homogenization. During ageing, the proteins covering the fat globule are replaced by the emulsifiers, and agglomeration and partial coalescence of the fat globules is facilitated. This is important for structure formation and air cell distribution during whipping and freezing. The emulsifiers are also important for the stability of the air cells, the walls of which they strengthen.

To put it more simply, the main benefits of emulsifiers in ice cream are:

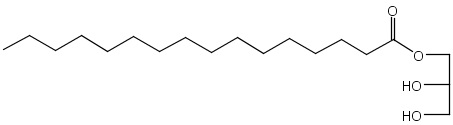

Mono- and diglycerides of fatty acids (E471) are the most commonly used emulsifiers in ice cream. They are produced from the interesterification of glycerol and fat, with the choice of fat determining the functional properties of the emulsifier.

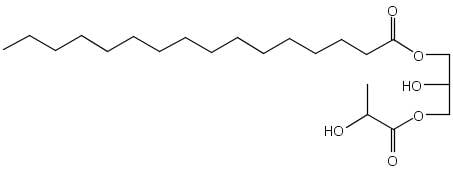

Mono- and diglycerides can be further esterified with organic acids. Lactic acid, for example, is used for the formation of E472b lactic acid esters of mono- and diglycerides of fatty acids (so-called lactic acid esters, or LACTEM). Lactic acid esters are more hydrophilic than mono-and diglycerides and are not commonly used in ice cream production. However, they have been found to have a significant influence on foam stability and texture when combined with mono- and diglycerides, allowing them to be used in the production of ice cream with high overrun.

Figure 2: Lactic acid esters of mono- and diglycerides of fatty acids (E472b)

Emulsifiers are always used in combination with stabilisers, which are hydrated and dispersed in water, reducing the amount of free water in the ice cream mix. They bind the water by means of hydrogen bonds or trap it in a three-dimensional network, resulting in increased viscosity.

The main functions of stabilisers in high overrun ice cream are to:

When it comes to choosing stabilisers, there’s far more choice than there is with emulsifiers, with most regions allowing a wide range of options. The most commonly used stabilizers in ice cream are:

Palsgaard recently set out to create a solution for the production of ice cream with overrun as high as 150 – 180%. Our key goal was to achieve a level of quality (in terms of sensory attributes, melting resistance and storage stability) that was comparable to standard ice cream.

Our trials included ice creams with fat levels from six to ten per cent. We used vegetable fat, and whey powder and/or skim milk powder as milk-solid non-fat. The use of whey powder also meant that the protein level was low in some of the trials.

The ice cream was produced in our pilot plant using an HTST unit and a continuous freezer. After hardening, the samples were transferred to a storage freezer at -18°C. To evaluate storage stability, heat-shock tests were carried out by increasing the temperature to -10°C for four days, after which the samples were returned to the storage freezer.

Sensory properties, as well as melt-down properties, were evaluated in both the samples that had been exposed to heat shock and those that had not. Melt-down properties were analysed at a controlled temperature of 25°C over 90 minutes.

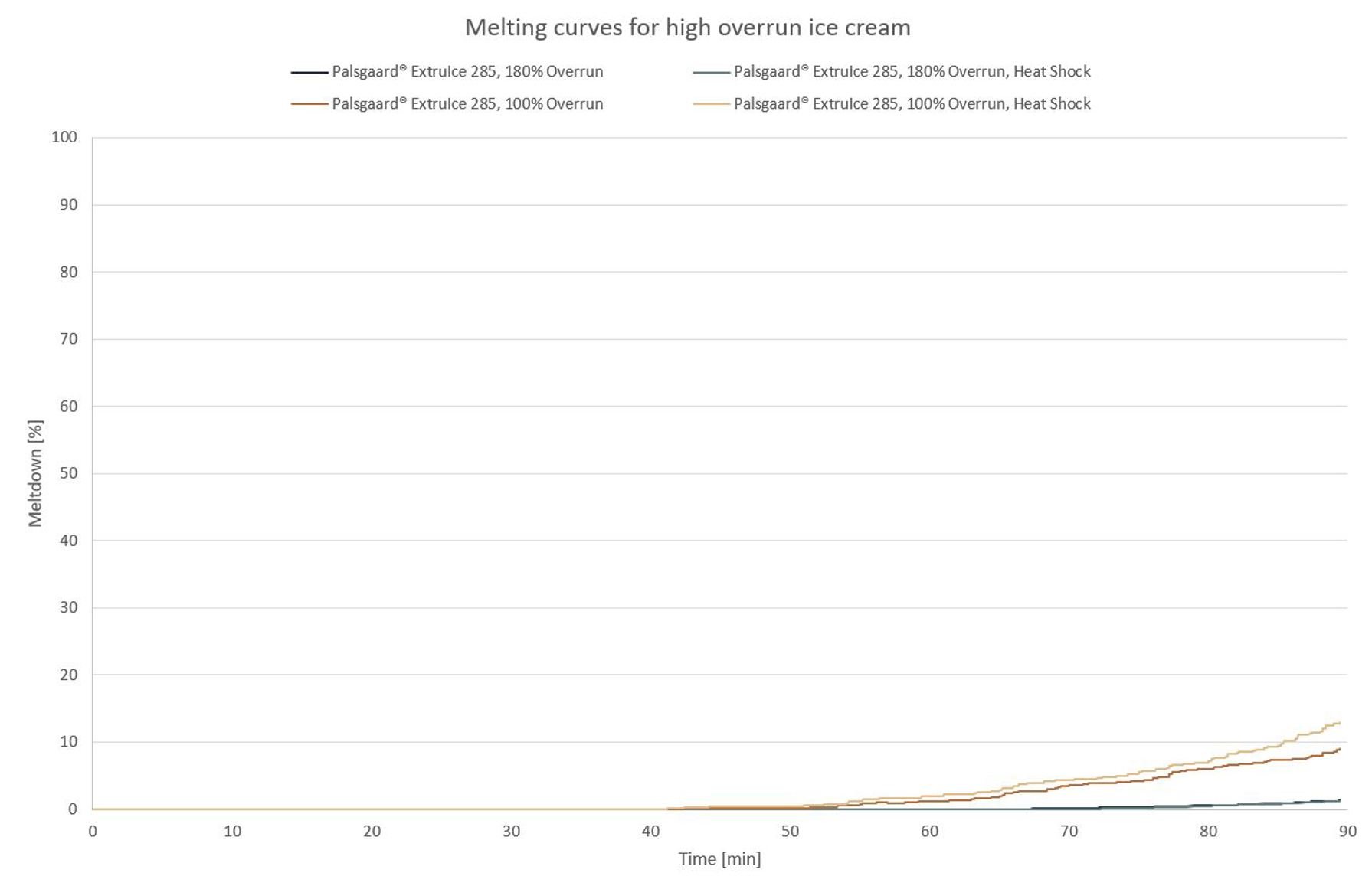

In order to obtain an ice cream with high overrun and homogeneous air cell distribution, it was necessary to apply higher shear, so the dasher speed in the continuous freezer was increased. Additionally, the cylinder pressure was increased to facilitate finer air cell distribution. Higher shear meant a higher degree of churning out in the freezer, and therefore stronger air cell walls and higher stability, which was confirmed in the melt-down and heat-shock tests. Figure 3 shows the melting curves of 10% fat ice creams with 180% overrun. Results for ice cream stored at constant temperatures as well as heat-shocked ice cream are shown. For comparison, the melting properties of a 10% fat ice cream with 100% overrun are also shown. Both ice creams were stabilised with Palsgaard® ExtruIce 285.

In Figure 3 it can be seen that less than 10% of the 100% overrun ice cream stored at constant temperature had melted. When this sample was exposed to heat shock, 12% of the ice cream melted during the 90-minute test period. The samples with 180% overrun were very stable, with less than 2% of the ice cream melting after 90 minutes. Shrinkage was not observed in any of the samples.

The use of Palsgaard® ExtruIce 285, which contains lactic acid ester of mono- and diglycerides, had a tremendous effect on both processing and melting, as well as the sensory qualities of the ice cream. Adding LACTEM facilitated the production of high-overrun ice cream with a stable structure. Furthermore, it enhanced sensory properties by creating a creamy and full-bodied ice cream. Even the high-overrun ice cream exposed to heat shock had a creamy and smooth mouthfeel without iciness. The high-overrun ice creams were softer but still melted more slowly than a standard ice cream.

It is clear that ice cream manufacturers now have a new cost-cutting tool that can be used without sacrificing quality. By using Palsgaard® ExtruIce 285they can produce ice cream products with high overrun while still keeping a creamy, smooth and full-bodied texture and a pleasant mouthfeel. Add to that the fact that it offers excellent storage stability, and the result is an ice cream that satisfies consumers in every way.

Palsgaard brings decades of expertise and innovation to the table. With our deep understanding of emulsifiers, stabilisers, and functional ingredients, we have continuously pushed the boundaries of what is possible in the industry.

Our dedicated team of scientists and technical experts stay at the forefront of research and development, ensuring that our solutions are cutting-edge and tailored to meet your specific needs.

When you work with Palsgaard, you benefit from our commitment to excellence and our ability to provide innovative solutions that give you a competitive edge.

TROUBLESHOOTING BY PALSGAARD

TECHNICAL ARTICLE

TECHNICAL ARTICLE

TECHNICAL ARTICLE

TECHNICAL ARTICLE

TECHNICAL ARTICLE

TECHNICAL ARTICLE

TECHNICAL ARTICLE