TECHNICAL ARTICLE

TECHNICAL ARTICLE

Many fans of chocolate milk might favour a creamy, luxurious drink as their go-to indulgent treat while others tend to prefer lighter, more refreshing options. Thomas Hvid Kruuse, one of Palsgaard’s experts in chocolate milk, highlights some of the factors manufacturers need to consider when creating their recipes, and what Palsgaard can do to help.

“We always work closely with our customers and once we know their requirements, in terms of whether they want to create a chilled or ambient product, or who their target audience is, we can use our expertise and we can do some tests in one of our global application centres and find a system that works.”

- Thomas Hvid Kruuse, Senior Application Specialist, Palsgaard A/S

Chocolate milk can be found on shelves and in fridges all around the world, but the taste and look of this ever-popular product can vary widely from one region to the next.

Another issue, of course, is that consumers around the world have different taste preferences and while many manufacturers believe creating a creamy luxurious chocolate milk is the ultimate goal, this isn’t always the case, according to Thomas Hvid Kruuse, Palsgaard’s Senior Application Specialist for Dairy and Ice Cream.

Thomas explains: “A few years ago I visited a customer in Asia to present a chocolate drink to them. We knew that people in Europe wouldn’t really like this drink because although it tasted like chocolate, the mouthfeel was not creamy enough. However, the customer in Asia was very excited about this because it was exactly what they wanted. In Asia, they considered the mouthfeel of this chocolate milk to be perfect because they said it was refreshing. We didn’t question it because we listen to our customers and work with them to create what they want.”

“These differences in consumer taste preferences can make it difficult for manufacturers, but generally in Europe, and also in the Middle East, consumers want a creamy sensation from their chocolate milks, and they don’t want them to be refreshing.”

Palsgaard can accommodate regional preferences because it is just a case of choosing the right emulsifier and stabiliser system, according to Thomas, but there are some technical challenges for manufacturers to be aware of which might affect the creaminess of the mouthfeel.

Thomas says: “Chocolate milk can be produced in different ways. The stabiliser base, for example, is usually carrageenan or Microcrystalline cellulose (MCC)”

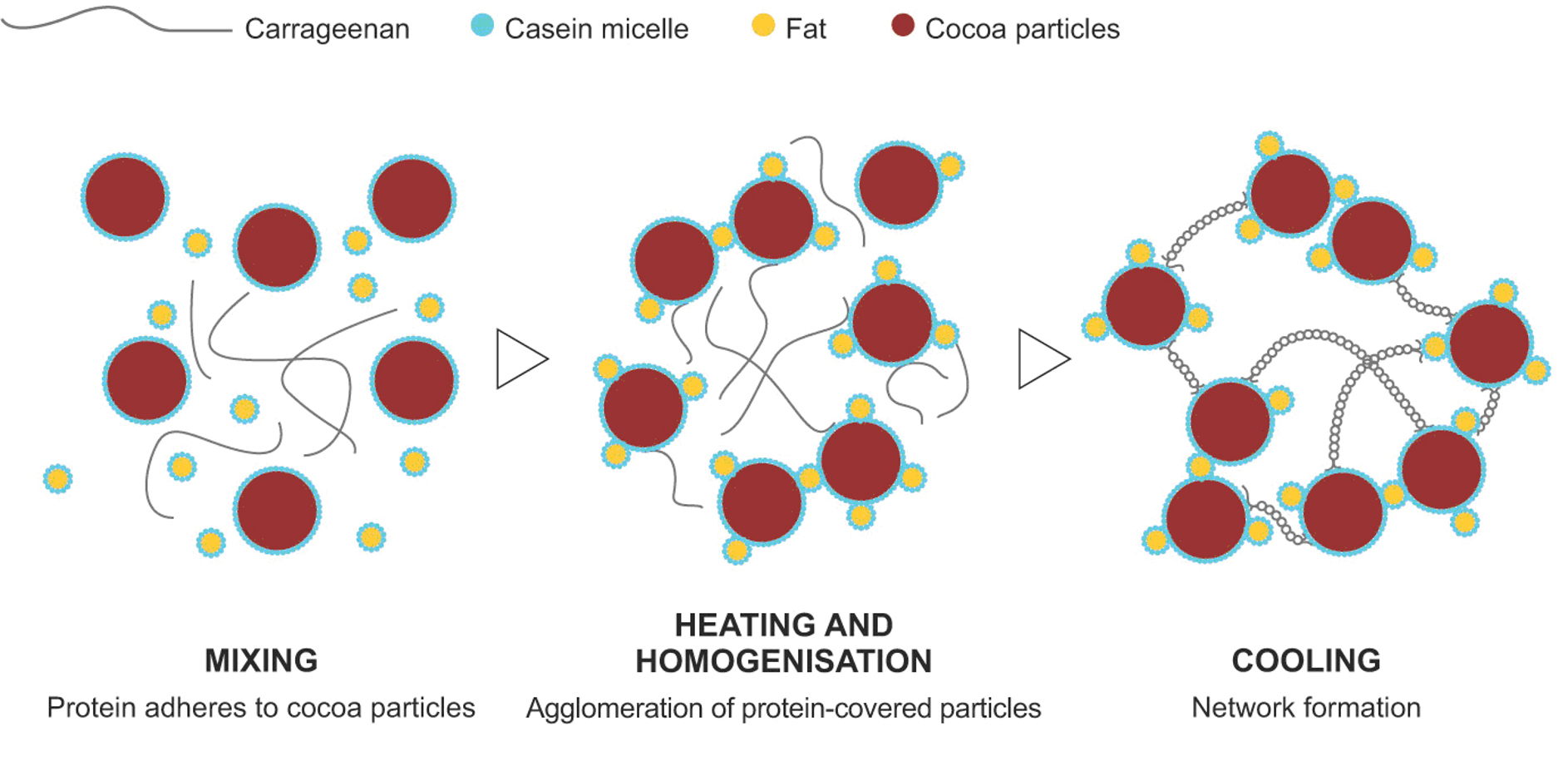

Carrageenan, which is extracted from seaweed, is by far the most commonly used stabiliser in chocolate milk.

Thomas says: “Carrageenan in general works well with dairy products because there is a synergy between the casein proteins in the milk and the carrageenan, that prevent the insoluble cocoa particles from sedimenting, additionally, it provides the creaminess in the chocolate milk.”

“So, although carrageenan in itself is a little bit of an expensive product, the strong synergy tends to result in a very powerful effect, even in a low dosage of these systems.”

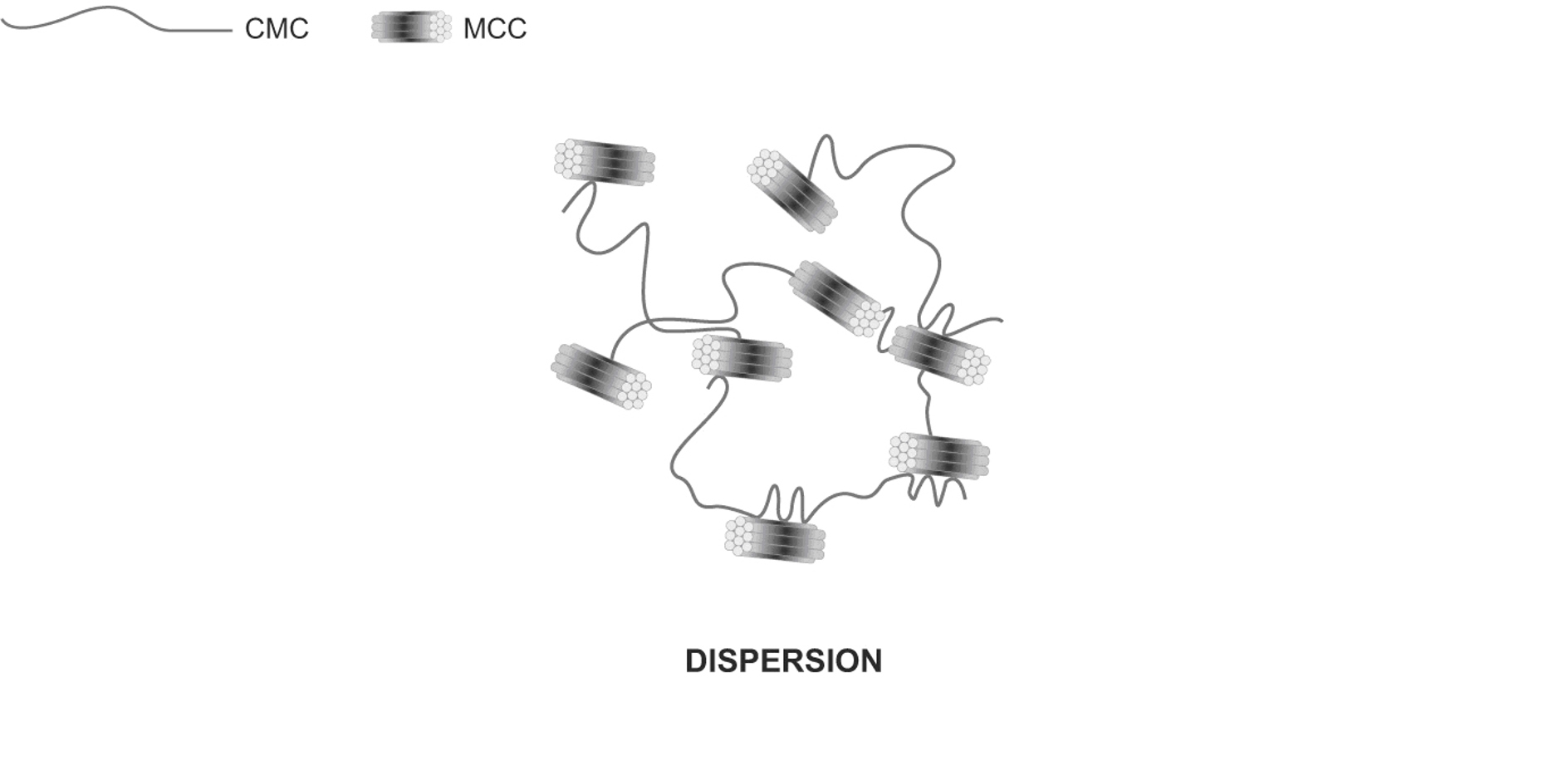

Meanwhile, with an MCC-base there are different things to consider.

Thomas says: “If, for example, one producer of chocolate milk has four different suppliers of milk powder and the four different suppliers have maybe a slightly different composition in the milk powder – one milk powder might have more calcium or a different protein content for example – then these are all things that might affect and influence the carrageenan base. When you use MCC however, you don't have to worry about those things because it's flexible and very functional.”

Palsgaard can work with pasteurised, UHT-treated and sterilised products and it has three key systems in its Palsgaard® ChoMilk range of stabiliser and emulsifier blends, which of which plays a different role in the production of chocolate milk.

An example of a carrageenan-based product for chocolate milk is Palsgaard® ChoMilk 150.

Thomas explains: “Palsgaard® ChoMilk 150 is our solution for standard chocolate milk because it is very cost-effective. It gives good properties for the suspension of the cocoa particles and the mouthfeel, and it can be used in both pasteurised and UHT products.”

However, if it is difficult to cool down the product below 25°C after production or if the storage temperature is above 30°C, then Palsgaard® ChoMilk 173 is a more suitable option.

He says: “If you live in a warmer country where you may not have the same refrigerated supply chain as in some developed countries, or perhaps the consumer doesn't have the cooling capacity like others have, then using Palsgaard® ChoMilk 150 is not a good idea.”

“If you live in Saudi Arabia for example, and you leave the chocolate milk on the kitchen table for a while in 40°C heat, then with Palsgaard® ChoMilk 150 as the stabilizing system you would quickly lose the functionality of the product.”

This is where Palsgaard® ChoMilk 173, takes centre stage. Containing both carrageenan and MCC, it’s recommended for chocolate milk drinks with low protein content. Thomas says: “It’s a very flexible product and besides offering a creamy mouthfeel, with Palsgaard® ChoMilk 173 you don't have to worry about these kinds of storage conditions and temperatures. It can also be used in pasteurised and UHT chocolate milks.”

Completing the trio is Palsgaard® ChoMilk 170, which is another MCC-based product, but as Thomas explains, it’s a different type of MCC, and the system is mainly used for sterilised products.

He says: “They are quite different. The requirements for the stabiliser system in retorted or stabilised products are different because the heat treatment is very harsh. “A normal heat treatment would be around 140°C for maybe two to four seconds, but when you're talking about sterilized or retorted products, it's normally 120°C for 15 or 20 minutes, so it's a very long time. It means you need a very specific system to be able to protect the protein and perform in this environment.”

Palsgaard can also help manufacturers who want to get the perfect mouthfeel for a low-fat variant of chocolate milk.

Lowering the fat content will immediately alter the mouthfeel of chocolate milk, offering less creaminess, and the product will need some adjustments in the doses of the Palsgaard® ChoMilk system, explains Thomas.

He says: “One point to note is that the emulsifier part of the system is connected to the content of fat. You could ask why you even need emulsifiers when you have a low-fat or a skimmed milk type of chocolate milk, but it’s important to understand that emulsifiers also help with another part of the process.

“You always have to mix the products and the ingredients this can result in a lot of foaming. If you don’t have the emulsifier, you will see a lot of foam and that could give you some problems in your processing.”

He adds: “One important step of the processing – whether it's UHT or pasteurised – is the homogenisation.

“It's a lot of bars of pressure and it's a very sensitive machine, so if you were going to run through a chocolate milk which has already incorporated a lot of air, and therefore a lot of foam, that could be a challenge for the manufacturer.

“By adding emulsifiers to your product – low fat or not – you will break the surface tension and you will see straight away that the foam disappears.”

The three Palsgaard® ChoMilk systems can help manufacturers adjust the creamy mouthfeel for many different chocolate milk recipes, even ones which are a little more unusual.

As an example, Thomas highlights a request he had from a customer last year who wanted to make a chocolate milk using another source of milk than cow’s milk.

He says: “It was a little bit challenging because I am not that big an expert in this particular milk! I know about the interaction between milk protein and carrageenan, but I didn’t know anything about the proteins in milk from this type of animal.”

Despite this, Thomas and his team were able to come up with a recipe that worked for this type of milk.

He says: “We always work closely with our customers and once we know their requirements, in terms of whether they want to create a chilled or ambient product, or who their target audience is, we can use our expertise and we can do some tests in one of our global application centres and find a system that works.”

TECHNICAL ARTICLE

TECHNICAL ARTICLE

TECHNICAL ARTICLE

TECHNICAL ARTICLE

TECHNICAL ARTICLE