FEATURE ARTICLE

TECHNICAL ARTICLE

If you remove the dairy components from milk chocolate to create a plant-based alternative you will face several challenges, and historically, many of the solutions have resulted in the over-use of cocoa butter and higher production costs. Here, two of Palsgaard’s application specialists – Orlando RamÍrez Gómez and Lasse Kolding Sørensen – explain how the company can offer cost-savings for manufacturers of both plant-based and regular chocolate with Palsgaard® AMP and Palsgaard® PGPR. The pair also shine a spotlight on two successful recipes they have created to highlight the versatility and quality of Palsgaard’s expertise in plant-based chocolate.

The plant-based movement is continuing its upwards trajectory and dairy-free chocolate is no exception. Consumers want their favourite chocolate treats available as a plant-based option, but they expect the same quality in both flavour and mouthfeel.

Consequently, the market for plant-based chocolate is a busy one and the sector is now recording 24% annual growth globally1 with Western Europe accounting for more than half (53%) of new chocolate product launches. This is followed by North America with 21% and Latin America with 8%.

Clearly, there’s a lot of activity – and consumer demand – but many dairy-free chocolate recipes contain a large volume of cocoa butter, which producers add to create the desired flavour and texture. The costs of production have historically, therefore, been high.

But Palsgaard now has a revolutionary product offering manufacturers an easy way to eliminate a substantial amount of this cocoa butter from the plant-based recipe, thereby saving costs. And what’s more, Palsgaard claims its product is twice as efficient as lecithin, so it can also deliver cost-savings to manufacturers of regular chocolate.

1Innova Database, CAGR – 2018 to 2020

"By replacing 0.4% of lecithin with 0.4% of Palsgaard® AMP 4455 it is possible to avoid overusing the cocoa butter. Palsgaard’s calculations show that for every MT of lecithin used, this translates into the overuse of as much as five MT of cocoa butter! All this unnecessary overuse can now be avoided by switching to Palsgaard® AMP 4455."

Lasse Kolding Sørensen, Senior Application Specialist, Palsgaard A/S

Making dairy-free chocolate is not an easy task and producers may face several challenges, according to Palsgaard’s Senior Application Specialist for Confectionery, Lasse Kolding Sørensen.

He explains: “Removing milk fat to create a plant-based alternative is not easy. Removing the fat creates a harder product and you also lose the sensation of eating milk chocolate. Also, you can’t just add any kind of fat because it has to be compatible with cocoa butter.”

This problem can be solved by replacing the milk fat with a milk fat replacer to create the creamy milk-chocolate-like meltdown. This will also preserve the bloom stability, which can occur in milk chocolate.

Sørensen says: “The next challenge is with the non-fat milk solids (milk powder), and this is important because the milk powder contains the lactose and the protein. When you take this out you must replace it with something else. Often the ingredients which are used to replace this can impart a floury or sandy mouthfeel, but we have discovered a rice compound, which is a mixture of rice sugar and rice starch. It provides a very good substitution for milk, and it doesn’t result in those grainy textures.

Incorporating 2% or 3% of additional cocoa butter into the recipe has historically allowed producers to create a non-dairy chocolate bar that best resembles traditional chocolate, but Palsgaard can now offer a cost-saving alternative, without compromising on taste or mouthfeel.

Orlando RamÍrez Gómez, Application Specialist, Confectionery at Palsgaard Mexico, says the way to eliminate this additional cocoa butter is to remove lecithin from the recipe and replace it with ammonium phosphatide (AMP), which is based on sunflower oil.

He says: “We have a wonderful system called Palsgaard® AMP 4455, which is a phospholipid. AMP was created specifically for chocolate with the aim of replacing lecithin because lecithin is known to impart off-flavours and unwanted colours.

“In addition to replacing lecithin for these reasons, AMP also reduces viscosity, and the good thing about this is you, therefore, don’t need to add that extra 2% or 3% of cocoa butter, which was only added in the first place to reduce the viscosity.

“Using sunflower-based Palsgaard® AMP 4455 or its rapeseed-based twin Palsgaard® AMP 4458 as a replacement for lecithin can help manufacturers from overusing a huge amount of cocoa butter every year, and therefore there’s a big cost saving there.”

Palsgaard® AMP 4455 is a highly functional alternative to lecithin, which Gómez describes as a “super AMP”, because it is more than double the strength of lecithin. This powerful alternative means that the additional 2% to 3% of cocoa butter is no longer required, and yet the flow properties of the chocolate are not affected.

Gómez notes that this option is not only perfect for manufacturers of plant-based chocolate but Palsgaard® AMP 4455 also works extremely well in traditional chocolate as a replacement for lecithin. Being more than twice as efficient as lecithin, switching to Palsgaard® AMP 4455 can bring considerable cost-savings, without compromising on quality.

High-quality lecithin may deliver cocoa butter savings of up to 4% but changing to Palsgaard® AMP 4455 will always deliver an additional 2%, which, for a medium-sized manufacturer producing 10,000 MT a year, translates to savings of €700,000, according to Gómez.

He says: “At Palsgaard we can help chocolate and plant-based chocolate manufacturers make that switch from lecithin to Palsgaard® AMP 4455. It might seem like a headache to change an existing recipe, but we can help make the transition seamless and straightforward. The cost savings manufacturers can make by switching to AMP are really quite big and we can help make this happen.”

Palsgaard also has the co-emulsifier Palsgaard® PGPR 4190, which will reduce the yield value of the chocolate. It will ensure unwanted air bubbles can escape and that the chocolate will fill the mould efficiently to perfectly create the desired shape.

Another benefit of switching to Palsgaard® AMP 4455 is that it can help manufacturers from a sustainability perspective.

It offers energy savings during production and – unlike lecithin-based recipes – it offers protection against rising raw ingredient prices.

Getting more out of the cocoa beans means companies can produce larger volumes of chocolate. And with environmental concerns growing in importance for both manufacturers and consumers, using less cocoa butter makes a lot of sense.

Sørensen explains: “By replacing 0.4% of lecithin with 0.4% of Palsgaard® AMP 4455 it is possible to avoid overusing the cocoa butter. Palsgaard’s calculations show that for every MT of lecithin used, this translates into the overuse of as much as five MT of cocoa butter! All this unnecessary overuse can now be avoided by switching to Palsgaard® AMP 4455.”

Palsgaard® AMP 4455 and Palsgaard® PGPR 4190 have been tried and tested in several ways and the company’s application specialists have created two recipe suggestions to help manufacturers understand the potential of these products:

The first is a plant-based moulded chocolate, which can be adapted to suit different recipes. The recipe, which uses both Palsgaard® AMP 4455 and Palsgaard® PGPR 4190, is made using sweet rice flour, which provides a moderate sweetness, a light colour and it preserves the pleasant mouthfeel, without a sandy or powdery sensation.

Sørensen says: “Using Palsgaard® AMP 4455 in place of lecithin means less cocoa butter is required in this recipe, and this will keep costs down to a reasonable level. Co-emulsifier, Palsgaard® PGPR 4190 helps ensure the air bubbles can escape, and that the chocolate will fill the mould efficiently to create the perfectly desired shape.”

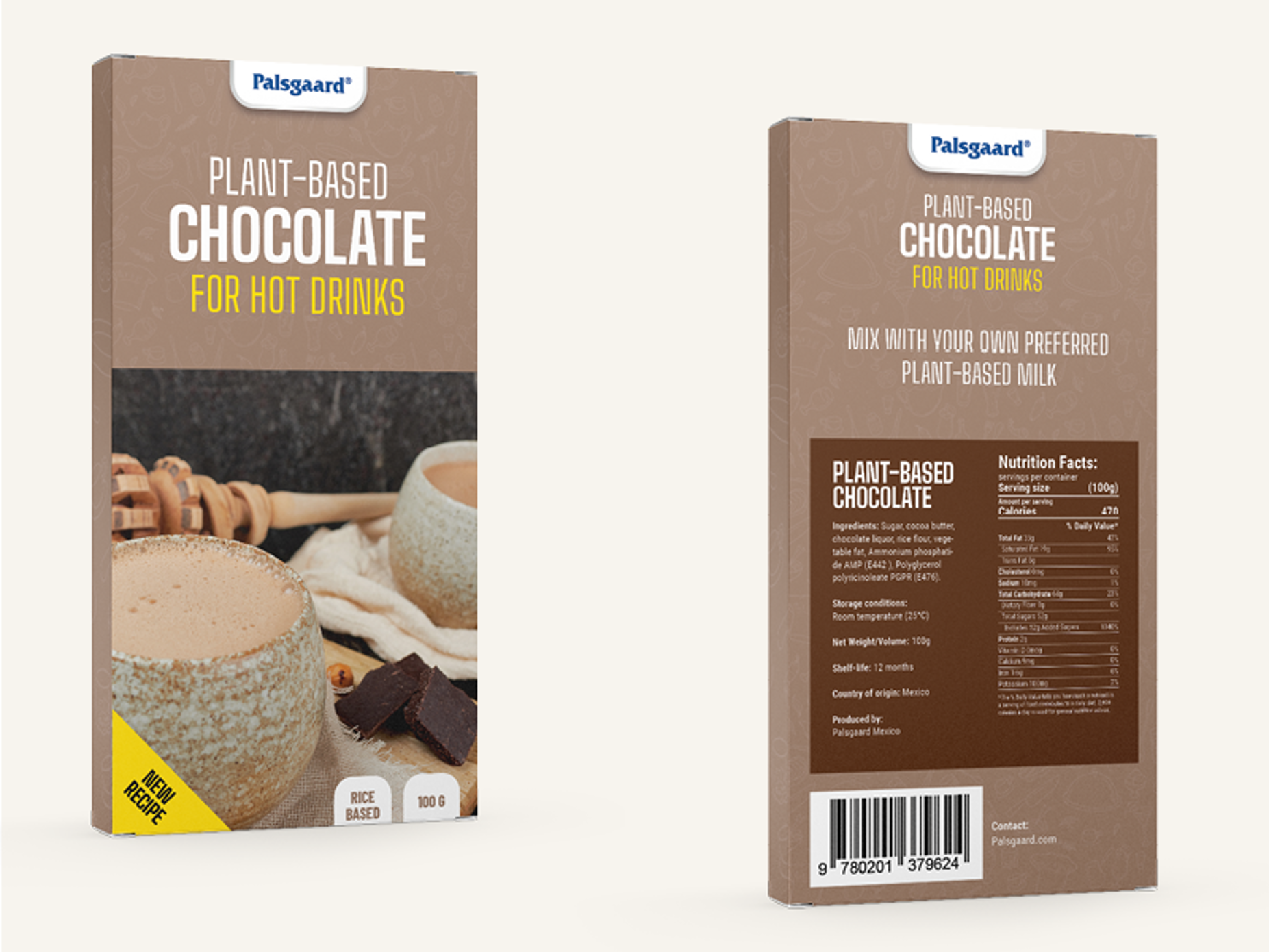

This recipe was created by Palsgaard for the Latin American market, where a chocolate tablet for creating hot drinks is a popular concept.

Gómez says: “This plant-based recipe has been tested with different plant-based milks, such as rice milk, almond milk and soya milk. It offers good stability, good solubility, no sedimentation and a good mouthfeel and flavour, especially when using almond or soya milk.”

For this recipe, Palsgaard® AMP 4455 was used as the primary emulsifier in place of lecithin, and Palsgaard® PGPR 4190 played a role as the co-emulsifier.

PRODUCT ADVANTAGES

Palsgaard® AMP 4455

Palsgaard® PGPR 4190

FEATURE ARTICLE

TECHNICAL ARTICLE

TECHNICAL ARTICLE

TECHNICAL ARTICLE