TECHNICAL ARTICLE

TECHNICAL ARTICLE

There is a growing demand for better-for-you cake mixes for home bakers. In our latest “how-to” feature, we introduce four new recipe concepts that demonstrate how Palsgaard’s Emulpals® 117 and Palsgaard® OilBinder 01 emulsifiers can help cake mix manufacturers replace margarine with healthier liquid oils.

Across the food industry manufacturers are adapting to the growing demand for healthier options, and the cake category, including mixes for home bakers, is no exception. Browse the cake mixes on offer at your local supermarket and you’ll come across plenty of products promising to meet a wide range of health needs. “It’s been important in cakes for a long time, but better-for-you can mean more than one thing,” says Rikke Bloch, Senior Application Specialist at Palsgaard. “Over the years, we’ve seen gluten-free, we’ve seen lean-label, we’ve seen reduced sugar, we’ve seen low fat. Then the vegan and plant-based trends came along.”

The picture also varies by global region, she says: “In Europe in particular, there’s a big focus on healthier cake mixes. The US is moving more slowly, but better-for-you is becoming more important there as well. So we always have our eyes on what’s happening in the market, listening to what our customers are telling us, and trying to help them create cake mix products that will appeal to health-focused consumers.”

Saturated fats, commonly in the form of shortening or margarine, remain a common ingredient in cake mixes, but they tend to raise levels of LDL cholesterol in the blood, increasing the risk of conditions like heart disease and strokes. Swapping them out in favour of polyunsaturated liquid oils like rapeseed and sunflower is one of the best strategies for creating better-for-you products.

“Cakes are typically high in fat, but they don’t have to contain the unhealthiest fats” Rikke says. “Switching from margarine to liquid oil is one of the best places to start if you want a healthier cake mix, because something that’s low in saturated fat is going to be much better for the heart.”

In order to highlight the ways cake mix manufacturers can respond to the better-for-you trend, Palsgaard has created four new recipe concepts. Designed with the needs of home bakers in mind, they can also be used by craft bakers. Alongside liquid oil, they feature Emulpals® 117 – a whipping emulsifier which provides efficient aeration and builds a uniform crumb structure – and Palsgaard® OilBinder 01 – a stabiliser which reduces oil leakage. As well as being low in saturated fat, the recipes offer additional health benefits.

“We wanted to show how innovative you can be when it comes to creating cake mixes with liquid oil.” Rikke says. “But you can’t do it without a good emulsifier.”

As well as being better for you, the four recipes show manufacturers how they can make life easier for home bakers. “That’s where Emulpals® 117 is very good,” Rikke says. “It’s our fastest choice – it delivers aeration in a few minutes, so home bakers can use a spoon and it doesn’t take too much time. It’s a great choice for mixes because people don’t want to be spending ten minutes with a hand blender. That convenience is a big plus point.”

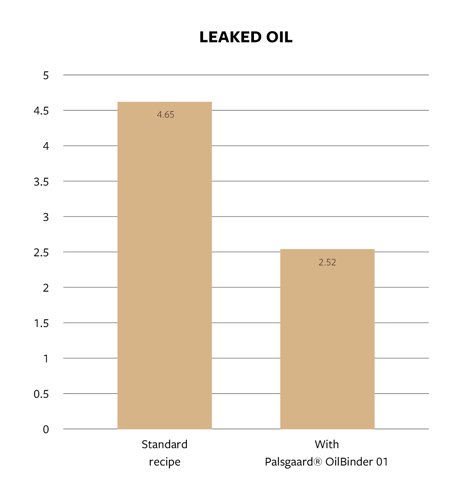

Another common challenge in oil-based cake recipes is that the oil can separate out. To overcome this problem, the recipes also include Palsgaard® OilBinder 01, a stabiliser usually used in confectionery applications, but which has recently been found to deliver positive results in bakery.

As well as helping to create softer and moister cakes, it keeps the oil in the cake, reducing the risk of “oiling out”, a phenomenon that can result in grease on the packaging and the fingers. It has been shown to reduce oil leakage to levels comparable to those found in cakes based on solid fat.

“Adding an oil binder keeps the oil in the mix, so consumers don’t get those greasy hands,” Rikke says. “It also means that they won’t notice any oil in the packaging.”

Palsgaard’s first recipe concept is for a mix that can be used to create not one but two delicious gluten-free snacks. “It’s very convenient and you can make two cakes or snacks in one – both choux pastry and churros,” Rikke explains. “Normally the process for making choux pastry is quite complicated. You’ve got to heat up the water and the margarine, and then you’ve got to put the flour in, and then the eggs. But with Emulpals® and Palsgaard® Oilbinder 01 in the mix, consumers can do it all in one step without any machinery. It’s very easy – a child can do it at home. Then you just have to transfer it to the baking paper and put it in the oven and you’ve got choux pastry. After that, you can fry the same mixture, and you’ve got churros.”

The recipe doesn’t have to be gluten-free – a version with flour would offer the same level of convenience.

Olive oil is rich in antioxidants and healthy fats and its benefits in areas such as cardiovascular health are well known to consumers. “When you tell people there’s olive oil in a cake, they think it’s healthier,” Rikke says. “It also gives products a nice Mediterranean feel.”

Palsgaard’s next concept – a lemon cake made with olive oil – makes the most of these benefits and dispels some traditional notions. “Some people think you can’t use olive oil in a cake,” Rikke says. “This is a recipe to tease them – ‘What? Olive oil in a cake?!’ But we actually found that in addition to a great crumb structure and mouthfeel – and the health benefits of olive oil – this cake tastes great.”

The concept includes a variation in which 100g of pickled pineapple with chilli is added for a spicier flavour. Alternatively, a salt and sugar mixture can be sprinkled on top after cooling.

Packaging example for an olive oil cake variations mix made with Emulpals® 117 and Palsgaard® OilBinder 01.

Packaging example for an olive oil cake variations mix made with Emulpals® 117 and Palsgaard® OilBinder 01.

Palsgaard’s third concept features another ingredient with an impressive range of health benefits. Almonds are believed to boost energy, improve memory, offer anti-ageing benefits, improve digestion and promote bone health.

The recipe also overcomes many of the difficulties commonly associated with making pies at home. Bakers just need to put all the liquid ingredients into a bowl before adding the dry ones and stirring the resulting batter for two minutes. The dough can hold a range of different filling types, like fruit and jam, and delivers good crumb structure and mouthfeel. “It’s very difficult to make a pie at home,” Rikke says. “This concept shows how better-for-you mixes can help consumers create something that tastes as good as a pie from a bakery. It’s very easy.”

Chocolate cakes are a familiar favourite but can be a source of headaches for home bakers. They are often crumbly and lack structure and preparation can involve a complex series of steps (often both butter and chocolate must be melted, and other ingredients incorporated with a hand mixer.)

Palsgaard’s final concept is a super-moist chocolate cake. Unlike the traditional mud cake on which it is based, it contains oil rather than butter, and cocoa instead of chocolate, and can be mixed using the simple all-in-one method. The resulting fluffy cake tastes amazing and offers good texture, structure and mouthfeel. “We used a standard Danish recipe,” Rikke says. “But we created our own version, just without the large amount of saturated fat or the cholesterol. The inclusion of Emulpals® in the mix also allows home bakers to make the cake in one simple step.”

Packaging example for a reduced-fat easy-bake chocolate mud cake mix with Emulpals® 117 and Palsgaard® OilBinder 01

Packaging example for a reduced-fat easy-bake chocolate mud cake mix with Emulpals® 117 and Palsgaard® OilBinder 01

All the concepts include packaging, nutritional information, and images of the cakes they can be used to create. “We wanted to go a step further for our customers, so they can see what’s possible,” Rikke says.

It’s an example of Palsgaard’s commitment to going the extra mile. “Our main focus is on volume, crumb structure, and the uniformity of the cake,” she says. “But over the years customers have said ‘Can we put cream in this cake?’ Or ‘Why don’t we have some flavours in it?’, so now we try to help them take the appearance and taste of the final cake to the next level too.”

Palsgaard’s global application centres support customers in a range of ways, solving technical problems, and helping them bring products to market. Unsurprisingly, the manner in which they do so has changed in the last year and a half, but Rikke says the pandemic has brought some unexpected benefits: “Before Coronavirus, customers would sometimes come to us in Denmark, or we would go to them. We can’t do that now, but we still have meetings with colleagues and customers around the world – it’s just that it’s via video-conferencing. And in fact, now they’re much quicker to get in touch. They know they can have a call on Teams, for example, straight away, whereas in the past, it might have taken two or three months to set something up. It’s sped up the innovation process because the technical application experts are brought in much earlier, which helps establish trust.”

Rikke emphasises the importance of listening to customers. “What do they need? To reduce costs? To create a high-quality product? What kind of sugar are they using? To do the right thing for them, we need to have a lot of dialogue.” Meanwhile, manufacturers are increasingly interested in the fact that Palsgaard’s ingredients are produced in factories with a strategic focus on reducing our energy consumption and our CO2-emissions: “It’s one of the biggest things we can offer” she says. “And it’s something end-consumers are willing to pay for.”

Rikke says the driving force for the new concepts was to highlight the level of support Palsgaard can offer the growing number of cake mix manufacturers trying to create better-for-you options. “We wanted to show what’s possible. We’ve been the first mover in a lot of these areas, and there isn’t much that we can’t help with.”

TECHNICAL ARTICLE

TECHNICAL ARTICLE

FEATURE ARTICLE

FEATURE ARTICLE

FEATURE ARTICLE

EMULSIFIERS EXPLAINED

TECHNICAL ARTICLE

TECHNICAL ARTICLE