TECHNICAL ARTICLE

TECHNICAL ARTICLE

This article explores some of the challenges facing two key groups in the U.S. bakery sector: industrial producers of long shelf-life cakes, and manufacturers of cake premixes. We look at the consumer trends shaping these two segments of the American cake market, including demand for better-for-you and sustainably produced products. And we focus on what these changes mean for manufacturers’ choice of emulsifiers.

In 2018, nearly 190 million Americans used dry cake pre-mixes.¹ And for many of those who prefer to buy cakes that are already baked, long shelf-life is an important consideration.²

But while consumers’ appetite for premixes and long shelf-life cakes remains strong, their needs are changing. There is increasing demand for a wider variety of cakes, including better-for-you and free-from products.

Therefore premix manufacturers and industrial bakers both have to meet a growing number of consumer needs. Of course, people want high-quality products that are reasonably priced, but health-related and ethical considerations increasingly influence their purchasing decisions. American cake-eaters may variously expect their favourite products to be gluten-free, vegan, low-carb, egg-free, organic, low in sugar, low in saturated fat or low in trans-fat. The bakery industry has also been working hard to reduce partially hydrogenated oils, another ingredient increasingly linked to health risks. Meanwhile, as in other sectors, there is demand for leaner, simpler labels.

One area affected by such shifts is the choice of emulsifier. Emulsifiers fulfil vital roles in both premixes and long shelf-life cakes, but changing market needs mean that now may be the time to consider how they are sourced.

Environmental concerns are also increasingly important to consumers, nearly two-thirds of whom now expect companies to invest in sustainability.³

The bakery industry is no exception. Indeed, Mintel has predicted that sustainability will drive innovation in the sector over the next five years, with bakers expected to address the issue in new and creative ways4. At Palsgaard, we see direct evidence of this in our satisfaction evaluations, in which we ask our customers to rank the importance of different issues on a scale of one to ten. Sustainability now typically scores around nine.

Concern for the environment is fundamental to everything Palsgaard does. We have a strategic focus on reducing our energy consumption and our CO2-emissions. Since 2005, we have carried out a number of activities including making tangible changes to the energy sources used by our factories. For example, at our Danish plant, we switched from oil to straw combustion to fuel indoor heating and converted all industrial boilers from heavy fuel to natural gas. We also installed regenerative heat exchangers, which have boosted heat recovery efficiency by over 30%. Our Netherlands site, where we have installed over 800 solar panels, has run off only renewable energy since the start of 2018.

As well as being manufactured in factories with a strategic focus on reducing our energy consumption and our CO2-emissions, all our emulsifiers are plant-based, and sourced as sustainably as possible. Where we use palm oil ingredients, we rely exclusively on RSPO-certified raw materials, enabling us to offer our complete product range as Mass Balance (MB) or Segregated (SG) certified. By using RSPO-certified palm oil, we support improved conditions for local workers, conservation of natural resources and biodiversity, and long-term economic viability.

Our commitment to sustainability received official bakery industry recognition in 2019 when we received the American Society of Bakery Bakingtech 2019 award for innovation in sustainability.

Emulsifiers provide uniformity, aeration and crumb softening in cakes made from premixes. In the US, many manufacturers use emulsifiers carried via high-ratio shortenings, a process which effectively adds emulsifiers and fats at the same time. However, shortening, which can be high in saturated or trans-fats, is linked with a number of health concerns. And as a carrier for emulsifiers, it can require a complex preparation process.

In long shelf-life cakes, emulsifiers fulfil a wide range of functions, including aeration, softening, workability, and increased shelf-life. To achieve these benefits, many manufacturers use cake gels rather than shortening-based emulsifiers. However, gels can add additional steps to the production process, and generate high rates of wastage.

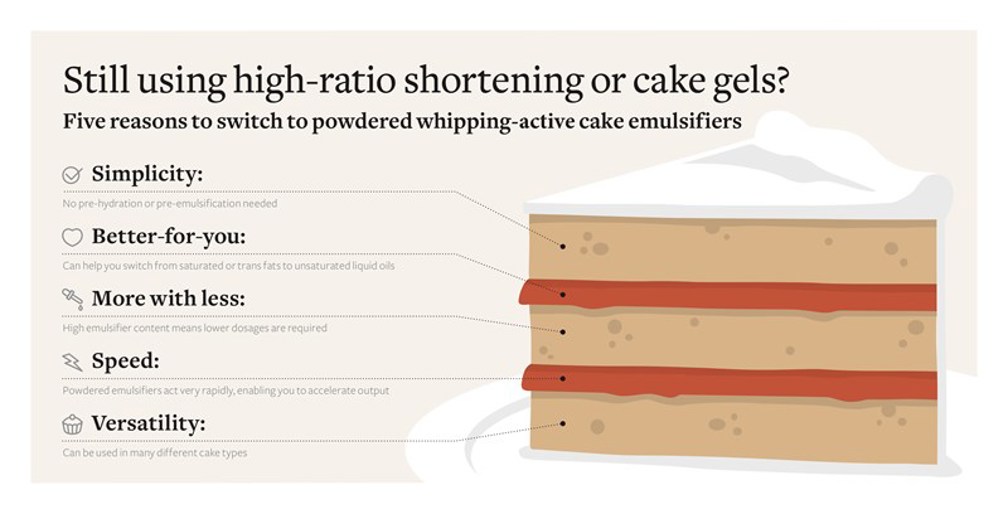

Fortunately, there is an alternative. Activated powdered emulsifiers are very different from emulsifiers carried on shortening. Because they are activated on starch in a highly sophisticated extrusion process, they offer a range of benefits over both high-ratio shortenings and cake gels, including:

Palsgaard offers two ranges of sustainably sourced, sustainably produced powdered whipping cake emulsifiers. Emulpals® is specially designed for premixes and Palsgaard® SA for long shelf-life cakes. Both are suitable for all cake types, whether aerated or non-aerated; they can be used in anything from sponge cakes to cupcakes, Swiss rolls to muffins.

Both product lines are completely plant-based, and free from allergens and trans-fats (not to mention sugar). And because most of the products contain only one or two emulsifiers and a natural carrier, they are label-friendly.

Emulpals® is a range of powdered whipping active cake emulsifiers offering many benefits in cake premixes. Custom-designed for the all-in production method for bakers’ mixes, they are fully activated, so no prehydration is required. In convenient powder form, they are easy to work with during recipe engineering and easy to dose during production and packaging. This means they deliver high aeration and softness, resulting in a uniform cake crumb and a smooth cake surface.

Emulpals® products are well known for their long shelf life and stability. Their performance over a long time scale is guaranteed ― all batches are tested for functional performance in real cakes. They have also shown good results in relation to storage in mixes at different temperatures. A large-scale trial found that Emulpals® products maintained high performance in a mix for 12 months when stored at both 68°F and 104°F.

Emulpals® can also help overcome common challenges with gluten-free cakes, which can be less structured than their traditional counterparts and tend to dry out quickly. With Emulpals® in the mix, the batter can hold high volumes of liquid oil without changing mouthfeel. Just as importantly, this can allow a shift from saturated to unsaturated oils, creating new opportunities for better-for-you products.

Emulpals® is suitable for all types of recipes, making product development much easier. To demonstrate this, Palsgaard has developed a series of recipes for cakes that are delicious as well as gluten-free, sugar-free, lactose-free, trans-fat-free, palm oil-free, and low in saturated fats. These benefits are achieved thanks to Emulpals®, which helps deliver:

The Palsgaard ® SA series of powdered, whipping-active cake emulsifiers helps industrial bakers deliver high-quality, better-for-you cakes. In convenient powder form, they are custom-designed for the all-in production method for industrial baking.

As a powdered ingredient, Palsgaard ® SA offers several benefits over shortening and cake gels. It reacts instantly when liquid is added to the batter, meaning no pre-hydration is necessary. It also offers consistent performance over time, and because it requires minimal manual handling, there is less risk of human error. Dosing is also simpler than with gels.

Scraping cake gel emulsifier residue out of a container can cause delays and wastage. By contrast, leaves its bag quickly, with only minimal amounts left behind. Powdered emulsifiers also take up less storage space, partly because less is needed for the same results and partly because the bags they come in are easy to stack.

Most importantly, customers can depend on Palsgaard ® SA’s stability and high performance. It offers a minimum of 18 months of shelf-life without loss of functionality, as well as stability during the baking and cooling processes and high tolerance to mechanical treatment.

Palsgaard offers much more than emulsifiers and the know-how to apply them to cakes. As a global emulsifier manufacturer with over 40 years of experience in developing cake recipes, we engage deeply with our customers to help find new ways to meet consumer demands on a global scale.

Our six well-equipped global application centres, including one in Mexico which services the US market, enable us to work closely with customers, testing and creating new recipes and solutions for cake pre-mixes to meet a wide range of consumer demands. Customers may also benefit from our temperature and moisture-controlled chambers for shelf-life tests, and from our equipment for measuring water activity, water content, volume and softness of the cakes after baking. Our industrial-scale mini-factories help us make realistic trials which can easily be scaled up to industrial size.

How many specialized emulsifier and stabilizer manufacturers offer their bakery customers industrial-scale testing facilities? Our central application facilities in Denmark include a fully equipped industrial bakery where realistic industrial pilot tests are carried out on a regular basis. Industrial-sized mixers and aerators feed a dual-zone continuous band oven to accurately reflect industrial conditions. This unique setup facilitates proper upscaling and increases the likelihood of success in the market. As well as guidance on equipment and support with recipe development, we can run trials in the factory and even start the commissioning of a new factory.

Customers can also be assured that Palsgaard is committed to finding new solutions in the emulsifier space. Drawing on the extensive capabilities of our R&D organization, Nexus, we are constantly innovating to develop new versions of Emulpals® and Palsgaard® SA, as well as other types of emulsifiers. Our customers can harness that innovation to create concrete benefits, both for themselves and end-consumers.

The many advantages of powdered whipping-active cake emulsifiers over shortening and cake gels are clear: stability, shelf-life, simplicity, efficiency, and opportunities for better-for-you products. Industrial bakers and premix manufacturers who partner with Palsgaard get all these advantages. And they can also be confident they’re working with a company with a genuine commitment to sustainability, as well as decades of expertise.

So it turns out you really can have your cake and eat it too.

Sources

¹ Statista ‘U.S. population: Do you use dry cake mixes (not cake flour)?’ https://www.statista.com/statistics/277447/us-households-usage-of-dry-cake-mixes/

² Lorenzi, Neil ‘Demand for longer shelf life, fewer preservatives spurs new packaging solutions’, ‘Snack Food and Wholesale Bakery’, 14 September 2017

³ Innova Markets Insights, Cited in ‘Sourcing challenges and sustaining a “circular economy”: The supplier view’, Food Ingredients First, 18 December 2018

4 Mintel ‘The Future of Bread, Bakery and Cakes: 2019’

TECHNICAL ARTICLE

TECHNICAL ARTICLE

TECHNICAL ARTICLE

FEATURE ARTICLE

FEATURE ARTICLE

FEATURE ARTICLE

EMULSIFIERS EXPLAINED

TECHNICAL ARTICLE