WHITEPAPER

FEATURE ARTICLE

In the competitive realm of consumer preferences, the visual allure of food products plays a pivotal role in shaping purchasing decisions. However, the issue of fogged and moisture-covered packaging obscuring the view of desirable food items has emerged as a significant concern, influencing both consumer interest and contributing to global food waste.

Bjarne Nielsen, Business Development Manager at Palsgaard, explains how plant-based anti-fogging additives can be an important tool to ensure the optimal appearance of plastic-packaged food products and beverages.

Startlingly, an estimated one-third of the world's food production is lost or wasted annually, representing a staggering 1.6 billion tonnes of food, with an approximate economic value of $1.2 trillion. A prime example is the United Kingdom, where an astonishing 40% of purchased bagged salads are discarded, totalling a remarkable 178 million bags. Addressing this challenge has prompted innovative solutions in the realm of food packaging.

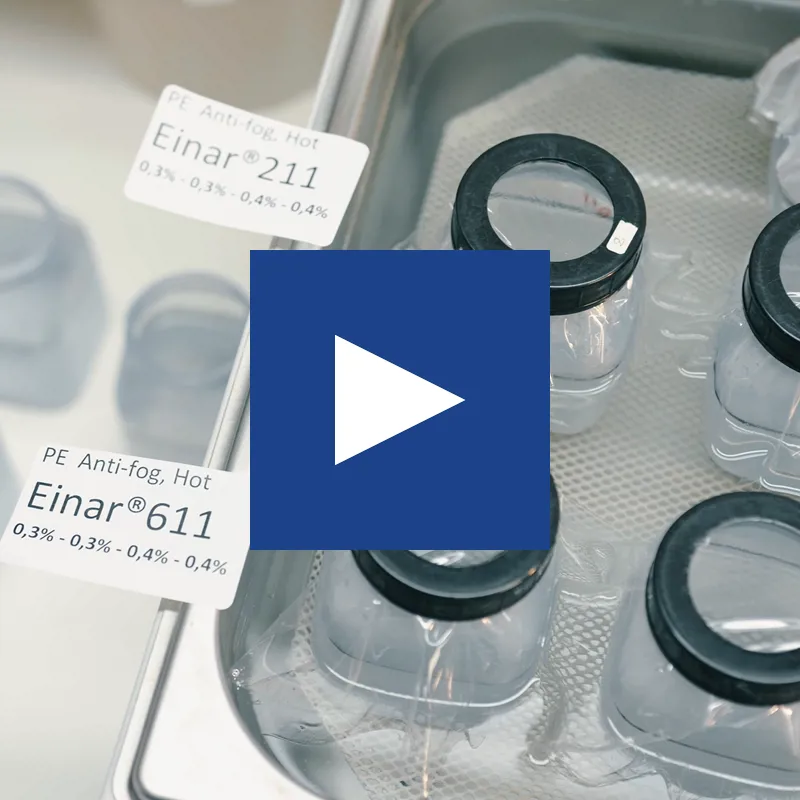

Palsgaard, a pioneering force in the industry, has introduced a range of surfactants specifically engineered to combat fogging and the accumulation of static electricity in packaging materials. These additives are strategically designed to ensure sustained clarity and visual appeal in transparent food packaging films and containers.

Fogging, a consequence of fluctuating humidity and temperature during transportation and storage, can lead to the formation of condensation droplets on the inner surface of packaging materials. Palsgaard's plant-based Einar® series of anti-fog additives can help manage this challenge. Rather than preventing moisture, they lower surface tension, facilitating the even spread of condensed moisture as a thin film. This not only preserves a clear view of the packaged food but also extends its shelf-life by safeguarding its freshness.

Static electricity-related challenges also impact plastic packaging, particularly during extended storage periods. Palsgaard's innovative additives serve a dual purpose, functioning as both anti-fogging and anti-static agents. These agents are seamlessly integrated into plastic packaging through specialized additives and masterbatches. Functioning akin to food emulsifiers, they effectively prevent fogging and dust accumulation by migrating to the packaging surface and continually renewing their efficacy.

Realizing the full potential of anti-static and anti-fog performance necessitates a comprehensive consideration of several factors, encompassing polymer type, raw materials, production processes, and end-product attributes. Palsgaard's plant-based additives, derived from a variety of vegetable oils such as rapeseed, sunflower, and palm oil, offer bespoke solutions tailored to meet specific user requirements.

A notable hallmark of Palsgaard's approach lies in its unwavering commitment to sustainability. The company's strategic focus on reducing its energy consumption and CO2-emissions, and utilization of certified raw materials from vegetable sources underscore its dedication to environmentally conscious practices. For food packaging producers seeking effective, sustainable solutions to fogging and static-related challenges, Palsgaard's anti-fogging and anti-static additives present a promising avenue.

Palsgaard's plant-based polymer additives are charting a path toward enhanced food packaging sustainability. By effectively addressing fogging, moisture buildup, and static issues, these additives offer a compelling opportunity to significantly curtail food waste, elevate the consumer experience, and foster eco-friendly practices within the industry. This innovative approach marks a significant stride forward in shaping the future of food packaging technologies.

WHITEPAPER

FEATURE ARTICLE

FEATURE ARTICLE

FEATURE ARTICLE

VIDEO FEATURE

FEATURE ARTICLE

TECHNICAL ARTICLE

VIDEO FEATURE

TECHNICAL ARTICLE