Attention to detail is key

Through our flexible setup, we are able to do highly precise and diverse testing to develop new solutions or assist customers in the study of their own additive solutions.

R&D SERVICES

When developing new polymer additives meticulous testing is absolutely vital to a successful outcome. At Palsgaard, our polymer development team is able to simulate both test scenarios and production processes. We develop and test under conditions similar to those found in a real polymer or masterbatch production environment – making both development and pre-production test runs faster and more precise.

VIDEO FEATURE

We know that meticulous testing is absolutely vital to succeed in an industry that never stands still. That’s why at our state-of-the-art Polymer Application Centre in Denmark we offer complete flexibility and a diverse range of testing for your specific needs.

Attention to detail is key

Through our flexible setup, we are able to do highly precise and diverse testing to develop new solutions or assist customers in the study of their own additive solutions.

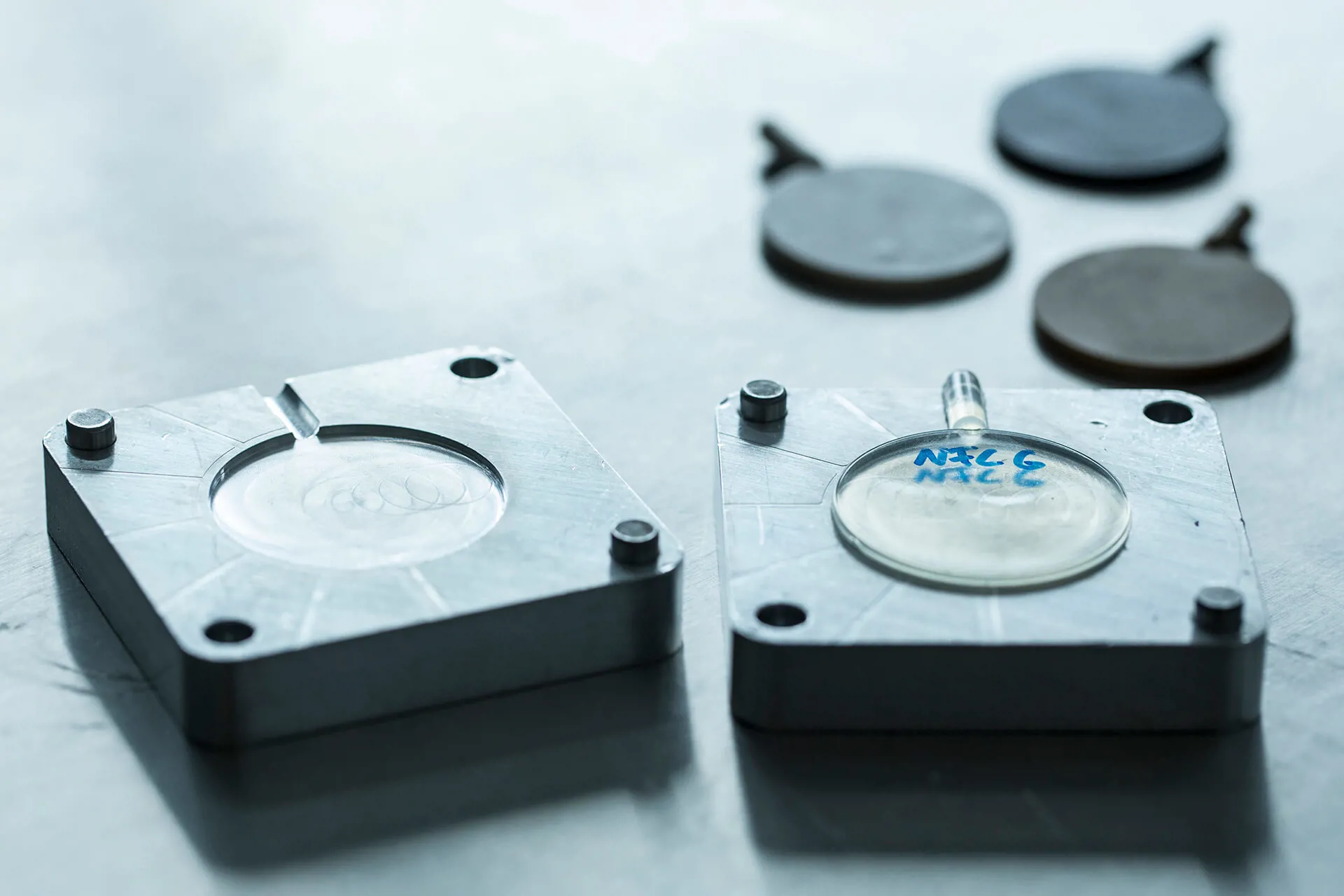

Injection moulding equipment

Our injection moulder allows us to test the performance of our Einar® mould release and anti-static additives in primarily PP and PE as well as certain engineering polymers.

Anti-stat testing

One of the main properties of the Einar® products is anti-static performance which we evaluate as static decay time and surface resistivity at both ambient and low humidity conditions.

Anti-fog testing

Anti-fog performance of the Einar® products is evaluated in hot- and cold-fog conditions in a 60 °C water bath and a 5 °C cooling cabinet, respectively.

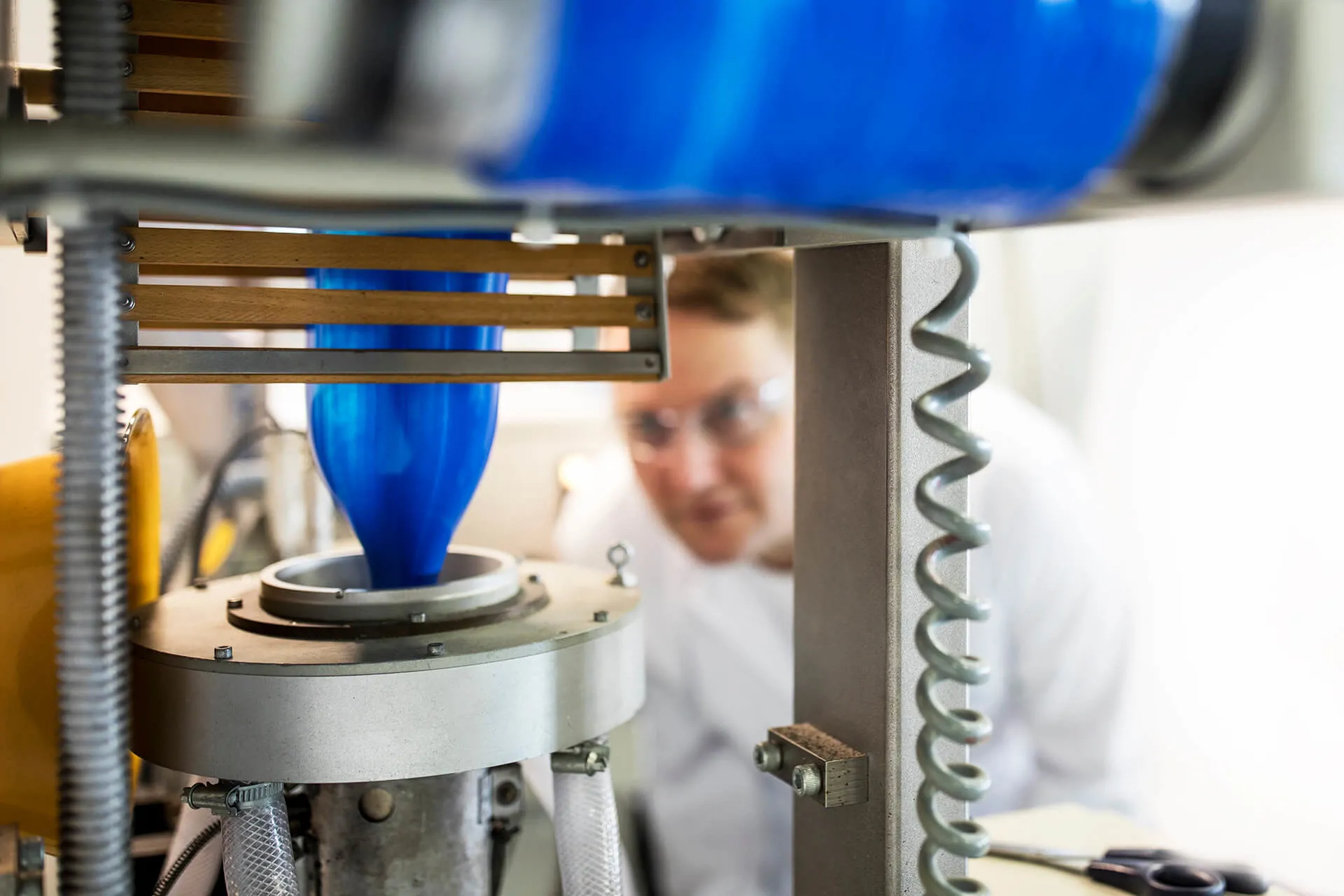

Blown film equipment

Our extruder allows us to test the quality of our Einar® anti-stat and anti-fog additives and compare their performance to current customer solutions mainly in PE films.

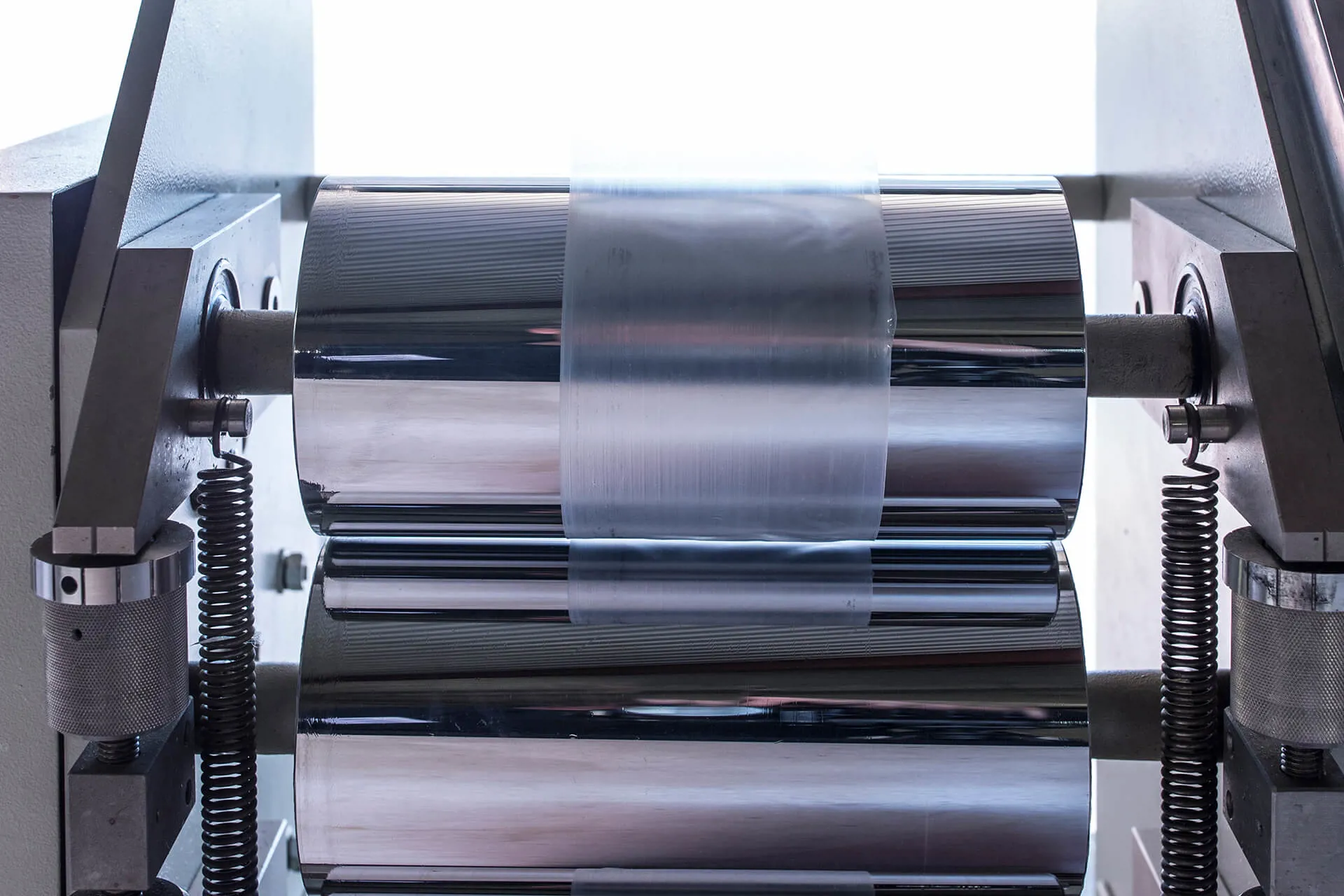

Cast film production

For further performance evaluation, we produce cast film through calendering of primarily PE, PP and PET materials.

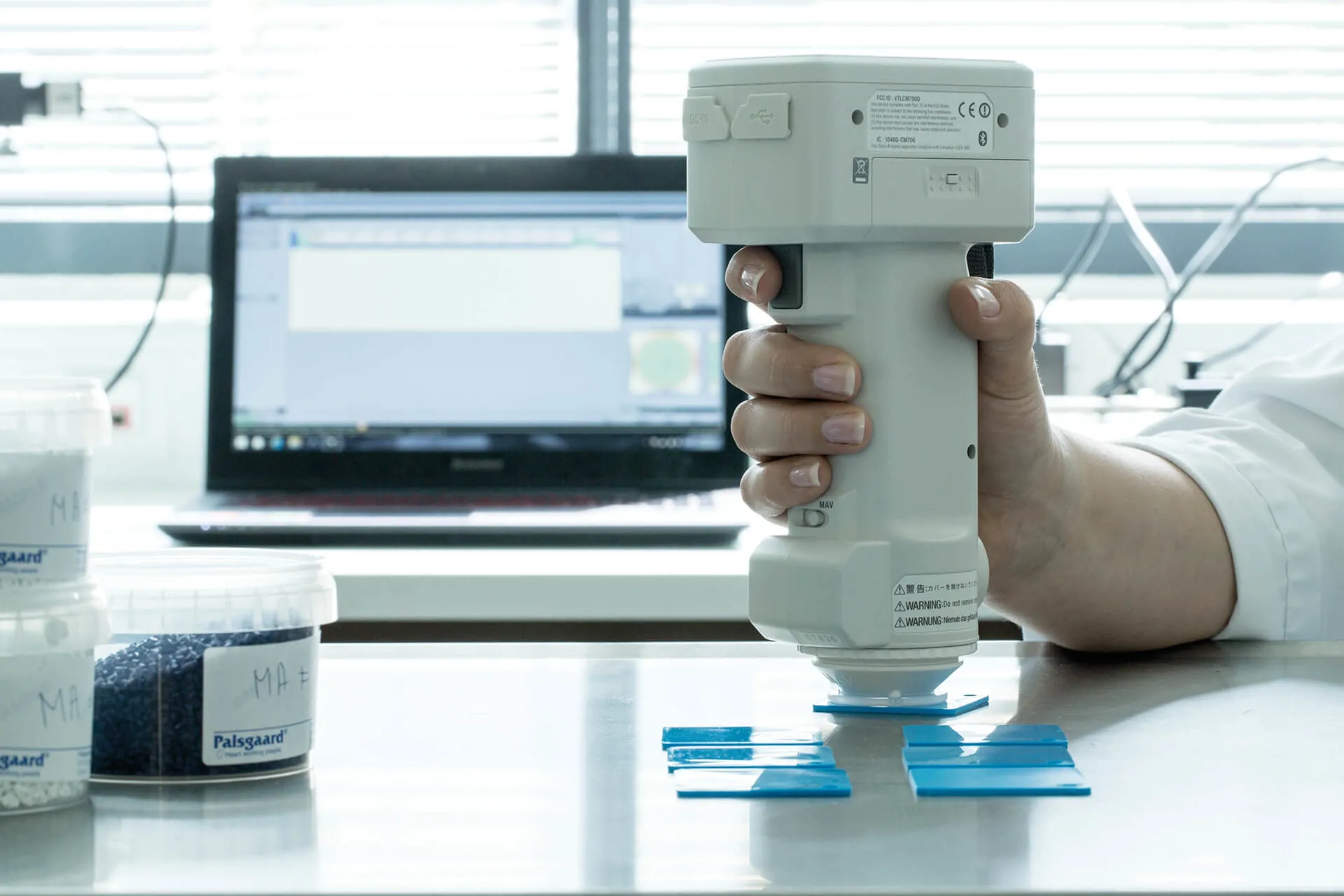

Colour masterbatch testing

Using a combination of filter pressure measurements, particle count and colour strength measurements, we developed and continue to test solutions for optimised pigment dispersion.

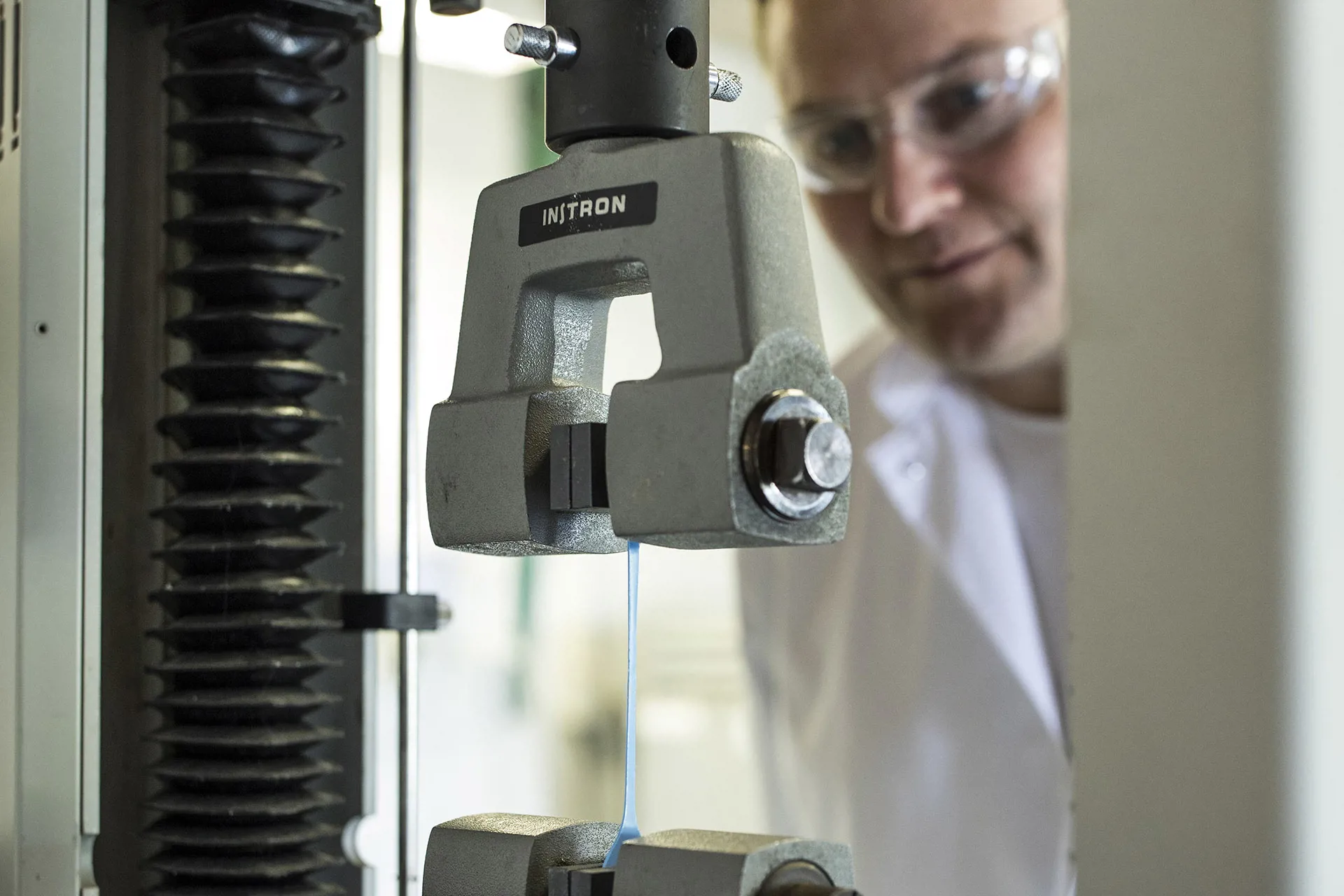

Mechanical testing

To ensure there is no adverse effect on polymers when formulating solution with Einar® products, we study the mechanical and surface properties of our developments.

Material characterisation

Through methods such as rheology and extraction, we are able to characterise the melt behaviour and chemical nature of our own and customer solutions.

PLANT-BASED AND FOOD-GRADE

PLANT-BASED AND FOOD-GRADE

PLNT-BASED AND FOOD-GRADE

PLNT-BASED AND FOOD-GRADE

PLANT-BASED AND FOOD-GRADE

PLNT-BASED AND FOOD-GRADE

PLANT-BASED AND FOOD-GRADE

PLNT-BASED AND FOOD-GRADE