WHITEPAPER

TECHNICAL ARTICLE

Palsgaard’s Einar® plant-based polymer additives are being adopted by manufacturers in diverse industries, valued for their performance and their potential to support sustainability objectives. Noverek/GEA, a respected supplier to the plastics industry in Mexico, has developed a calculation tool to help quantify the possible savings with Einar® mould release agents, including cycle time, energy consumption and part cost.

Injection moulders are continually looking for ways to optimise manufacturing costs while maintaining high product quality. At the same time, there is growing interest from regulators, brand owners and consumers in enhancing the sustainability of production processes. Plant-based polymer additives, such as Einar®, are designed to offer an alternative to conventional fossil-based products and may help manufacturers progress towards their cost and sustainability goals.

Operating under the umbrella of the Innecsus Group, Noverek Tecnología Química / GEA has been supplying Mexican moulders and masterbatch producers with Einar® plant-based polymer additives for many years. As a result, the company has also gathered extensive expertise in assisting its customers in the effective use of Einar® internal mould release agents from Palsgaard.

Polyolefin materials, such as polypropylene (PP) and polyethylene (PE), show some shrinkage when the melt solidifies, which can create demoulding as well as subsequent nesting problems. While mould release agents eliminate these risks by lubricating the interface between the part surface and the mould, they must be added with care to avoid undesired plate-out or deposits on the inner mould walls, clogging of mould vents and additive migration, for instance out of plastic packaging products into food.

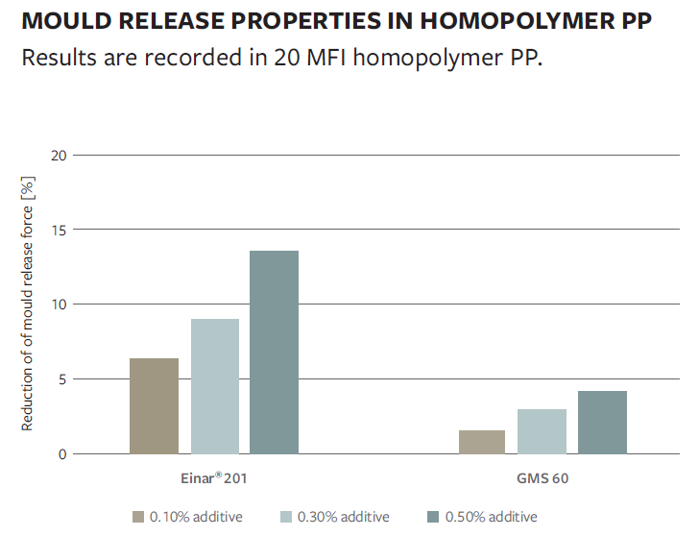

Einar® mould release additives are formulated to meet the requirements of PP, PE, PVC and polycarbonate (PC) injection moulding, as well as PP compression moulding processes. “Our monoglycerides are derived from palm oil (available as RSPO SG or MB certified), rapeseed, or coconut oil, providing a renewable alternative to many synthetic competitors,” explains Ulrik Aunskjaer, Global Business Director for Bio-Speciality Polymer Additives at Palsgaard. “In many cases, efficient performance has been demonstrated at lower concentrations than some conventional fossil-based amine and amide release agents.” (Fig. 1)

Next to combining proper mould release with high heat and processing stability, Palsgaard’s Einar® solutions also deliver a slip effect to prevent stacked parts from sticking and facilitate denesting in downstream operations. In addition, their anti-static properties minimise the attraction of dust in handling and packaging. All products are approved for food-contact and potable water applications according to international regulations.

In a recent project aimed at improving the productivity of a large water tank lid application (Fig. 2), Noverek/GEA suggested the use of Einar® 201 mould release. Initially, the customer had moulded the part at an overall process time of 110 seconds in a PP compound with a recycle content of 30% and no release additive.

“Convincing moulders to change an existing formulation requires solid know-how in both material properties and process optimisation,” says Erick Suarez, GEA managing director. “Backed by our long experience as Palsgaard’s distributor in Mexico, we knew that their bio-based Einar® 201 mould release product would not just ensure adequate lubrication in an ideal migration profile with low volatility, but also provide a number of significant added value benefits to the moulding process itself.”

In comprehensive trials at the customer’s plant, it was demonstrated that the mould release agent enabled a major reduction in process temperatures, reducing the cooling time and resulting in a 17-second faster cycle. Besides generating appropriate energy savings between 13-38%, this meant that the number of parts produced per day could be increased from 785 to 929, equivalent to a rise in machine productivity of approx. 18%.

In order to underscore these benefits more widely in the field, Noverek/GEA has developed a calculator tool to quantify the potential cycle time, energy and cost savings depending on the process parameters and the mould release concentration. In several other application cases, the tool showed possible productivity increases of up to 30%.

“In addition to these savings, manufacturers can capitalize on further beneficial side effects when adding Einar® even at low loading levels of only 0.2%,” Suárez points out. “For example, we found that the mould release agent can improve melt flow, helping customers reduce material costs by allowing them to increase the recycle content in the polymer formulation. It also works as an effective pigment dispersant, reducing masterbatch consumption without losing colour, and has shown to facilitate the purging of machines for faster resin or colour changes.”

Although Einar® 201 was developed by Palsgaard as a general-purpose mould release especially for PP injection moulding applications, many Noverek/GEA customers have been successfully using it also with other polymers, such as ABS, polyamides and bio-based materials, and in different processes from extrusion and blow moulding to lamination. Typical end products include dairy buckets, waste containers and jumbo bins, disposable cutlery, clothing clips and toys.

Einar® polymer additives are responsibly sourced from renewable vegetable oils, including options for RSPO SG or MB certified palm oil. These additives are designed to help address the growing demand for reducing fossil resource use and carbon emissions in the plastics industry.

“Masterbatch manufacturers, compounders and processors are increasingly seeking additive solutions that support regulatory compliance and help them work towards ambitious sustainability targets,” says Ulrik Aunskjaer. “Our Einar® additives are produced in factories with a strategic focus on reducing energy consumption and CO₂ emissions, contributing to a more responsible value chain from raw material sourcing to compounding and processing.”

By choosing Einar® mould release additives, customers may be able to reduce Scope 3 (indirect) emissions associated with their operations, while maintaining performance and cost efficiency.

The use of Einar® mould release agents offers measurable energy and cost savings by helping moulders reduce process temperatures and cycle time. A calculation tool developed by Noverek Tecnología Química/GEA in Mexico has proven a valuable means of quantifying these savings to moulders in the field, and Palsgaard is investigating the feasibility of deploying the tool also in other regions.

Further productivity gains derive from added benefits, such as improved masterbatch dispersion, part handling and machine purging. Last but not least, Einar® products are a perfect solution for moulders to reduce their carbon footprint ahead of increasingly strict decarbonisation regulations.

WHITEPAPER

FEATURE ARTICLE

FEATURE ARTICLE

FEATURE ARTICLE

VIDEO FEATURE

FEATURE ARTICLE

TECHNICAL ARTICLE

VIDEO FEATURE