WHITEPAPER

FEATURE ARTICLE

Modern packaging rarely relies on pure polymers. Additives are essential for functionality, safety, and cost-efficiency – but today, they must also meet strict sustainability and health standards. Palsgaard’s plant-based additives, derived from renewable vegetable oils and approved for food contact, offer compounders, converters, and brand owners a responsible alternative without compromising performance.

“Palsgaard’s bio-based additives are polyglycerol esters or glycerol mono-stearates made from vegetable fatty acids. Derived from animal-free, plant-based sources and produced under recognised sustainability standards such as RSPO, they provide a responsible alternative to fossil-based additives.”

– Ulrik Aunskjær, Global Industry Director, Bio-Speciality Additives

Food and non-food packaging applications depend on a wide range of polymer compounds, films, and foams designed for processability, safety, and usability. Additives are critical for achieving these goals. They enhance anti-static and anti-fog performance in PP and PE packaging – properties that maintain product aesthetics and extend shelf-life.

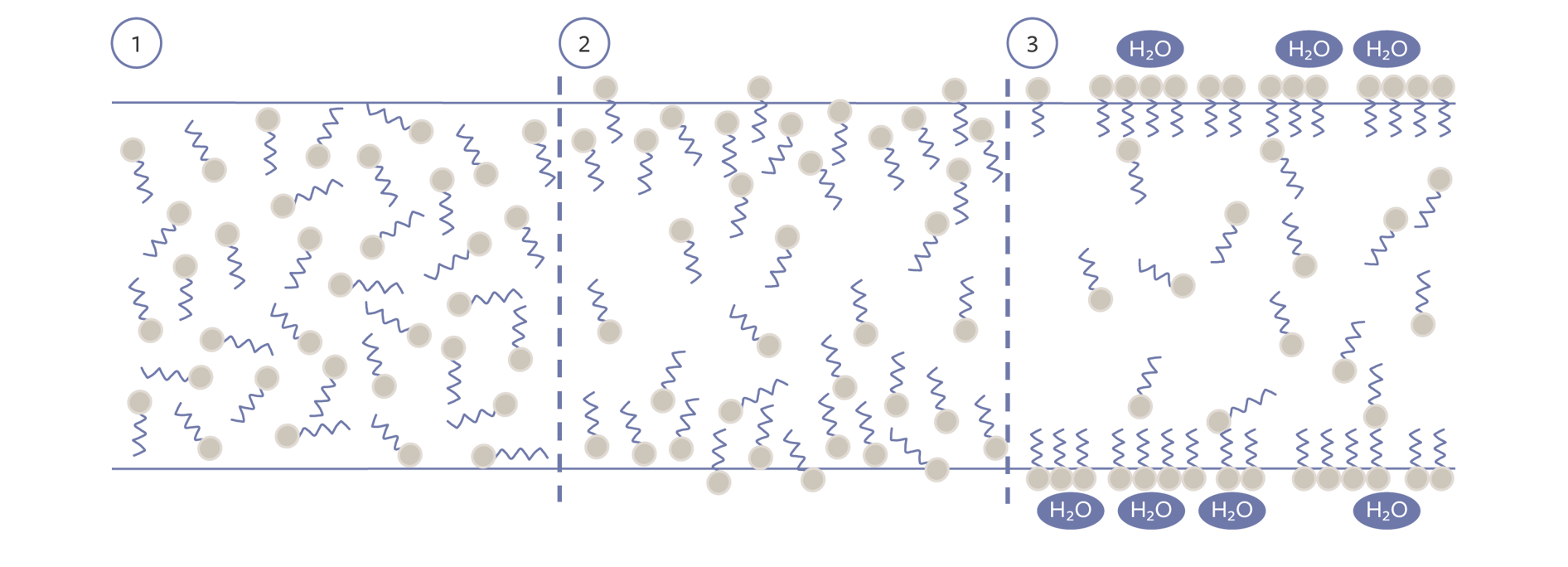

In most cases, these effects rely on migratory internal additives, but coatings are also available for applications where migration is not feasible. Beyond anti-static and anti-fog, additives serve as mould release agents, ageing modifiers, and pigment dispersants – functions that improve efficiency and product quality.

Palsgaard’s Einar® range of plant-based additives is derived from renewable vegetable oils such as palm, rapeseed, sunflower, and soya. These bio-based solutions provide a sustainable alternative to fossil-based additives like amines and amides—without compromising technical performance.

Key benefits of Einar® additives:

In a hungry world, packaging solutions must extend the shelf-life of products and reduce food losses while at the same time maintaining the aesthetic appeal of the packaged items. Palsgaard is addressing these needs with a range of surfactants designed to reduce the fogging and the accumulation of static electricity in the packaging material.

Fogging on the inner packaging surface can occur when moisture in the packaged product, such as food, condenses due to varying conditions of ambient humidity and temperature during transportation and storage. An effective anti-fog additive will lower the surface tension so that condensed moisture will spread as a continuous thin film across the surface. This preserves the clear view of the food and protects its freshness.

Another critical function of surfactants in packaging materials is to prevent the accumulation of static electricity on the surface. Static build-up attracts dust, which creates an unhygienic look of the product. Moreover, it can result in serious processing and downstream problems, such as reduced film rolling speed, congestions on conveyor belts, impaired stackability of moulded or thermoformed items, and poor sealability of packages for powdery food. In electronics packaging, it may even damage the packaged product. Palsgaard’s plant-based anti-static additives interact with ambient moisture to form a conductive layer that will effectively dissipate the static.

With roots in food emulsifiers since 1917, Palsgaard ensures all Einar® additives meet the highest safety standards. This is a significant benefit, especially with regard to the desired migration of anti-static and anti-fogging additives. Normally, there are strict migration limits for additives in food packaging to eliminate health hazards and prevent changes in the taste of the packaged food. However, as virtually edible additives, most of our plant-based Einar® products are not subject to these constraints. In fact, they can even help formulators and compounders reduce the overall additive concentration in the polymer without compromising their functional effectiveness. All are FDA and EU as well as kosher and halal approved for food-contact applications.

With anti-stats, for instance, this is measured as static decay time or surface resistivity. For fogging, tests are run to simulate cold storage of products such as salads and hot-fill applications such as newly cooked meat. In both scenarios, Einar® plant-based additives have shown that they can easily match or outperform the effectiveness of traditional fossil-based competitors, including amine/amide and polyethylene glycerols, at similar or lower concentrations.

As ageing modifiers in PE and PP compounds, they are successfully replacing amine and amide modifiers to support the release of excess blowing agents from foamed articles. Moreover, they have no stress-cracking impact on packaged electronic components. In injection and compression moulding plastics, they combine excellent mould release and denesting with high heat and process stability at low loading levels. And as natural alternatives to erucamide slip additives in thermoplastic polyesters such as PET, they add lubrication to plastic surfaces and lower the coefficient of friction while also promoting thermal stability and low volatility during processing. They also work well in combination with anti-blocking agents and can help reduce surface defects.

In addition, the plant-based technology has proven extremely effective for the dispersion of pigments, fillers, and other additives in polymer masterbatches at a significantly lower concentration than traditional waxes in the market. This means that pigment loadings can be reduced to achieve the desired colour strength, which saves cost, facilitates colour changes and enhances the sustainability profile of the polymer formulation.

As the packaging industry moves towards a circular economy, Einar® additives help customers meet ambitious sustainability goals by combining technical performance with responsible sourcing:

These product benefits are backed by Palsgaard’s broader ESG strategy, known as our Heart Working Commitments, which guide measurable actions across the value chain:

Together, these initiatives ensure that Einar® additives not only deliver performance but also align with global sustainability objectives and Palsgaard’s own ESG commitments.

Our sustainability efforts go hand in hand with technical excellence. At Palsgaard’s Polymer Application Centre in Denmark, we simulate real-world processing conditions to help customers optimise performance while meeting circularity and ESG goals. Producers are invited to request samples and benefit from expert guidance during qualification and implementation – ensuring every solution delivers on both technical and sustainability promises.

WHITEPAPER

FEATURE ARTICLE

FEATURE ARTICLE

VIDEO FEATURE

FEATURE ARTICLE

TECHNICAL ARTICLE

VIDEO FEATURE

TECHNICAL ARTICLE