FEATURE ARTICLE

FEATURE ARTICLE

In today’s plastics industry, cost-efficiency, safety, and sustainability are no longer optional – they’re essential. Brand owners and plastic converters are under increasing pressure to deliver high-performance packaging solutions that meet regulations, support circularity, and align with environmental goals.

Why masterbatches matter

Plastics compounders and converters face a common challenge: how to add functional properties to base polymers while maintaining efficiency, safety, and cost control. Achieving precise dosing and homogeneity with individual powders, pastes, or liquids can be complex and time-consuming.

For masterbatch producers, this creates both a challenge and an opportunity; how to provide additive solutions that combine technical excellence with responsible sourcing and circularity. Pelletised additive masterbatches solve this problem. By combining additives into a single, easy-to-handle format, they simplify dosing, reduce handling risks, and ensure consistent performance. For masterbatch producers, this is an opportunity to deliver value-added solutions that meet the needs of converters and brand owners.

The Einar® advantage

Palsgaard’s Einar® range of plant-based, food-grade additives is designed to help masterbatch producers stand out. Derived from renewable vegetable oils such as palm, rapeseed, sunflower, and coconut, these additives offer a bio-based alternative to conventional fossil-based additives like amines and amides—without compromising performance.

KEY BENEFITS OF EINAR® POLYMER ADDITIVES:

Why use masterbatches with Einar®?

As Einar® Polymer additives are neat additives, achieving a consistent dosing at very low concentrations can be challenging for converters. Masterbatch producers bridge this gap by delivering ready-to-use pelletised concentrates that:

By incorporating Einar® additives, masterbatch manufacturers can strengthen their portfolio with high-performance solutions that balance cost with safety and renewable sourcing.

Application areas

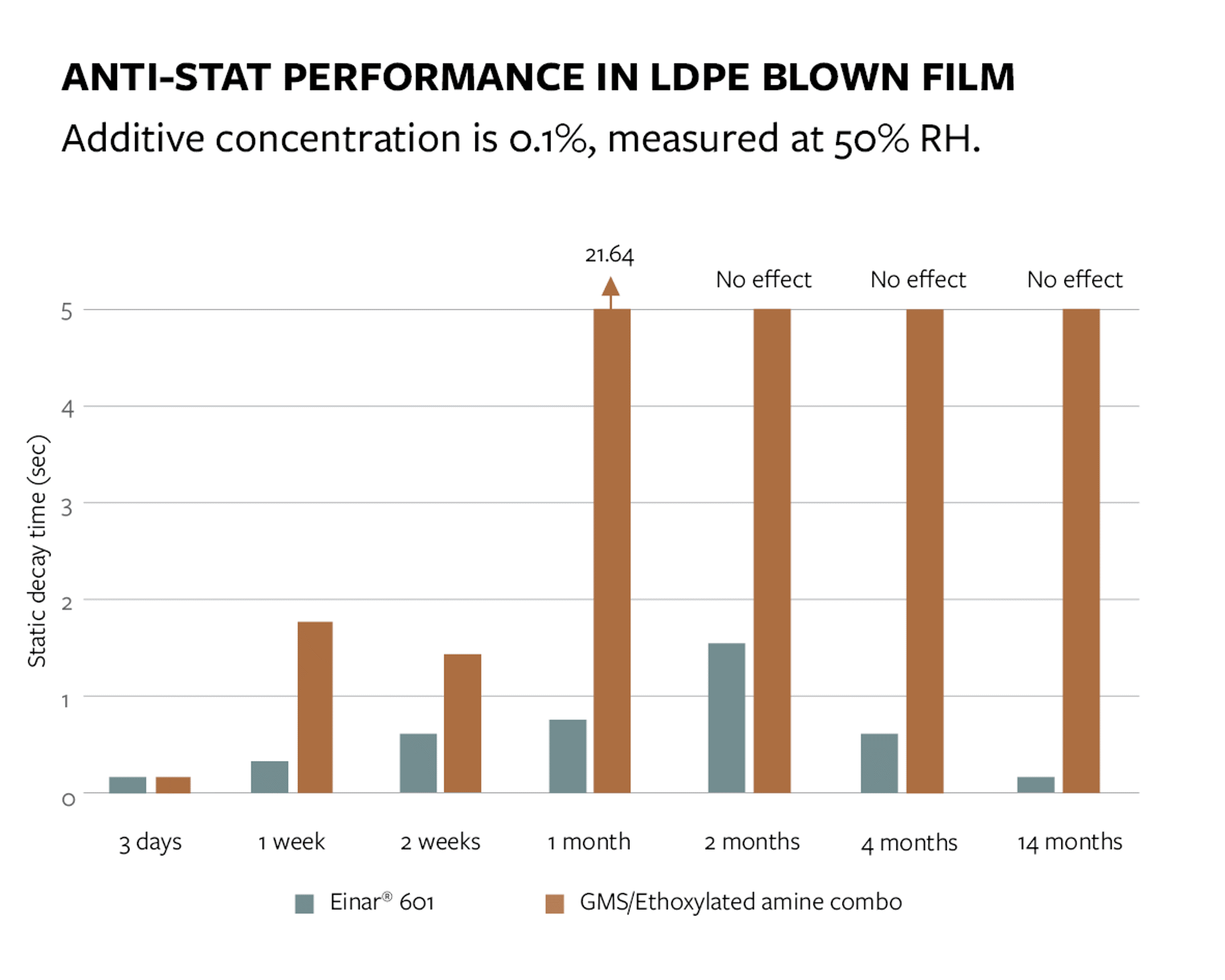

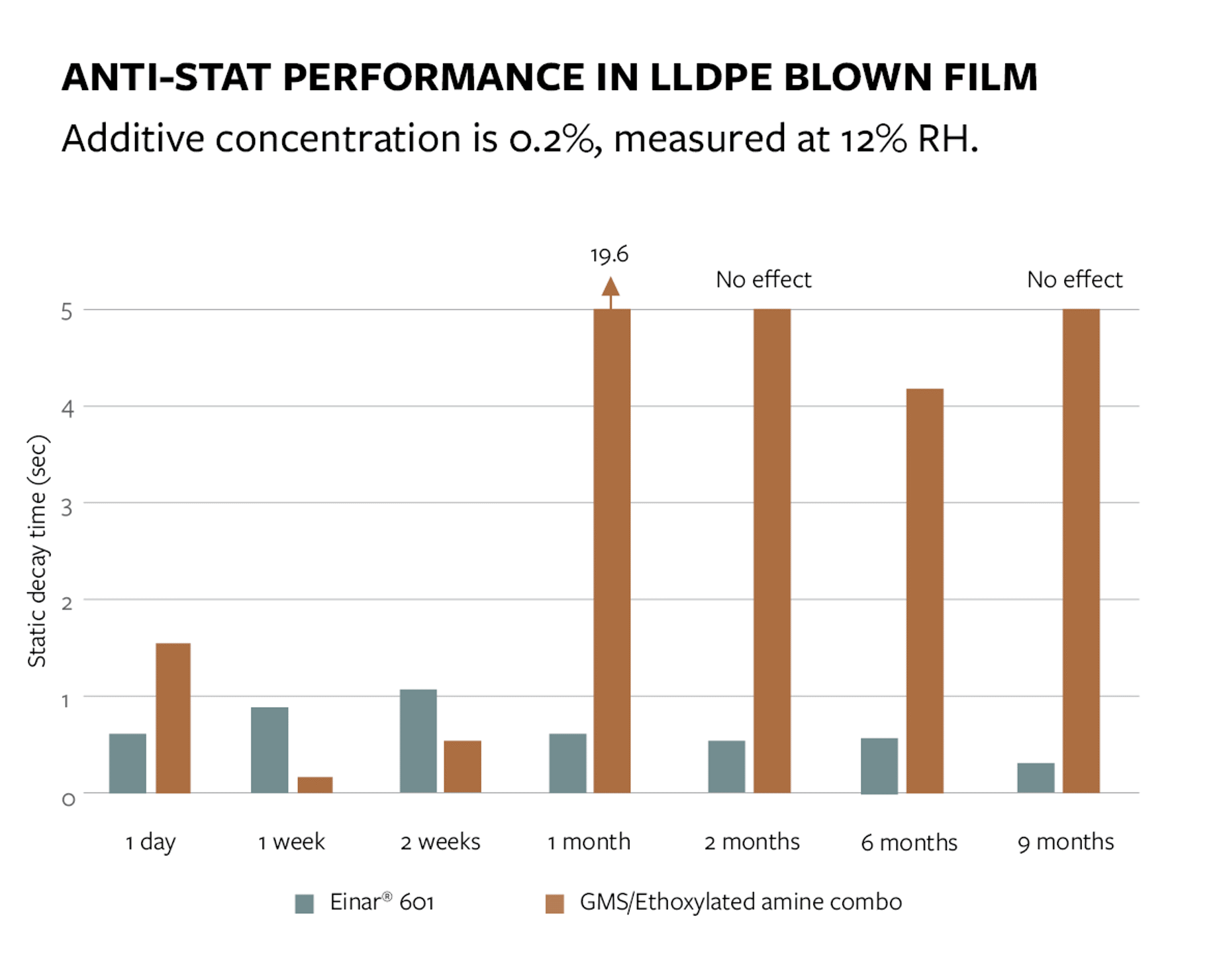

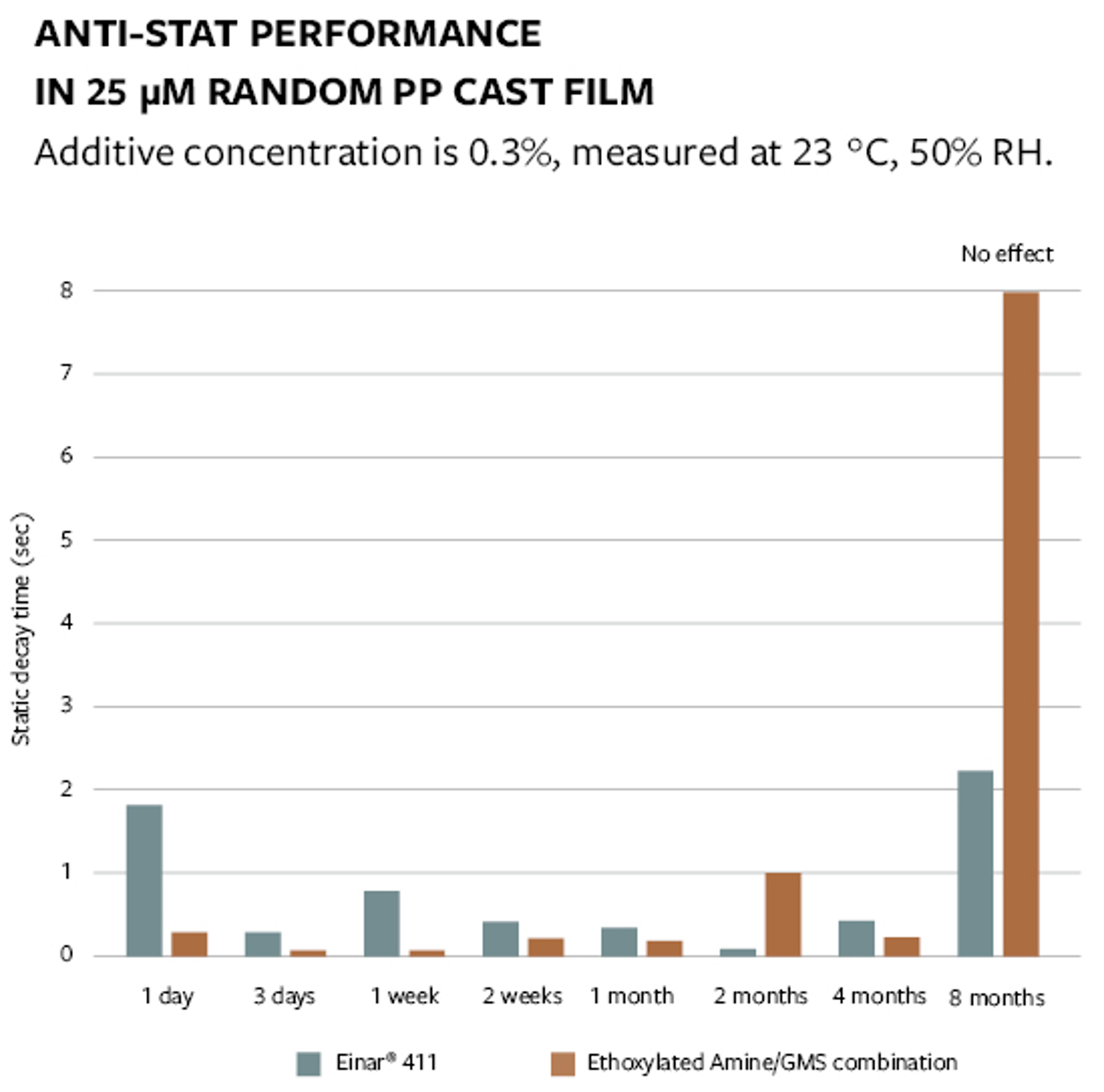

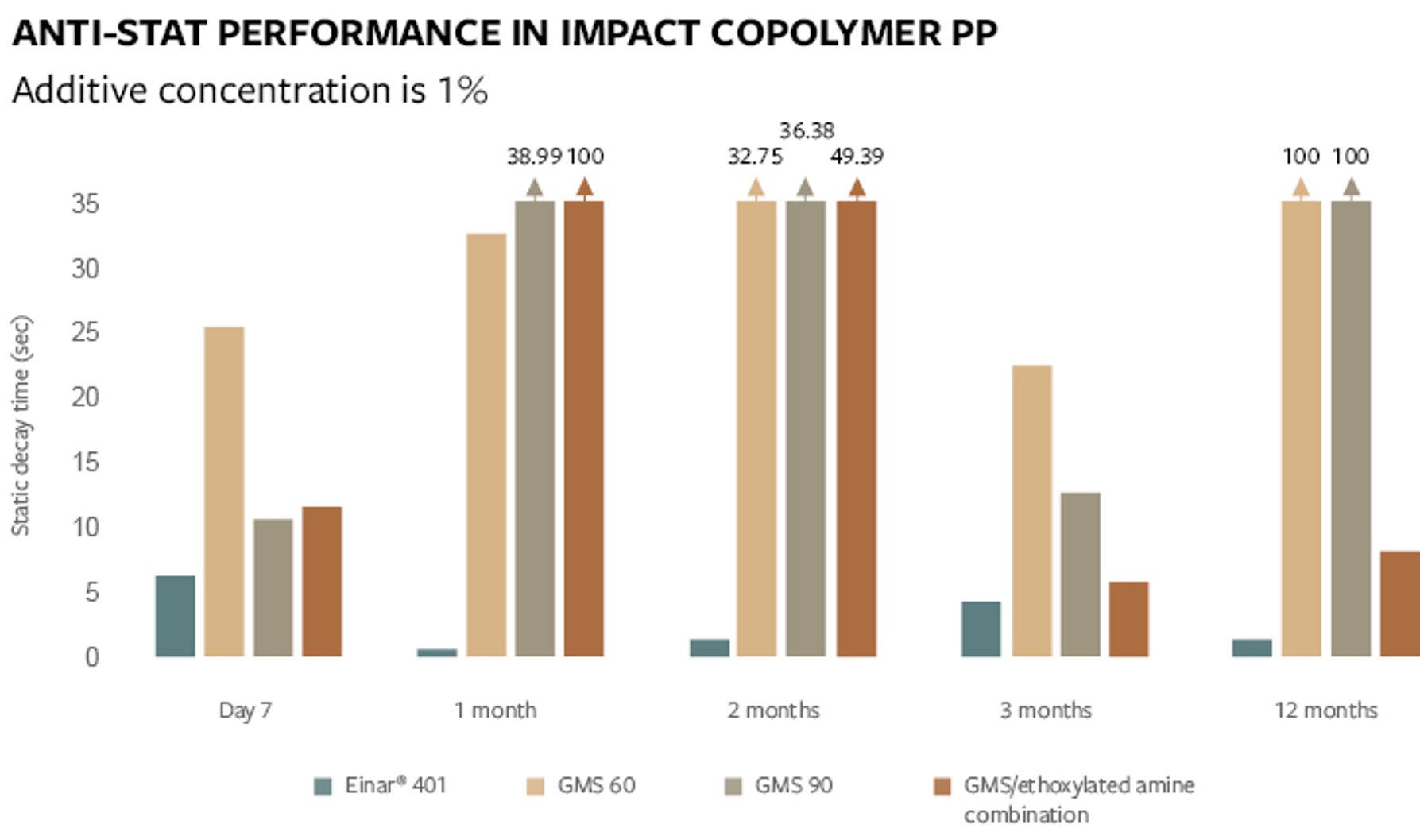

ANTI-STATIC SOLUTIONS

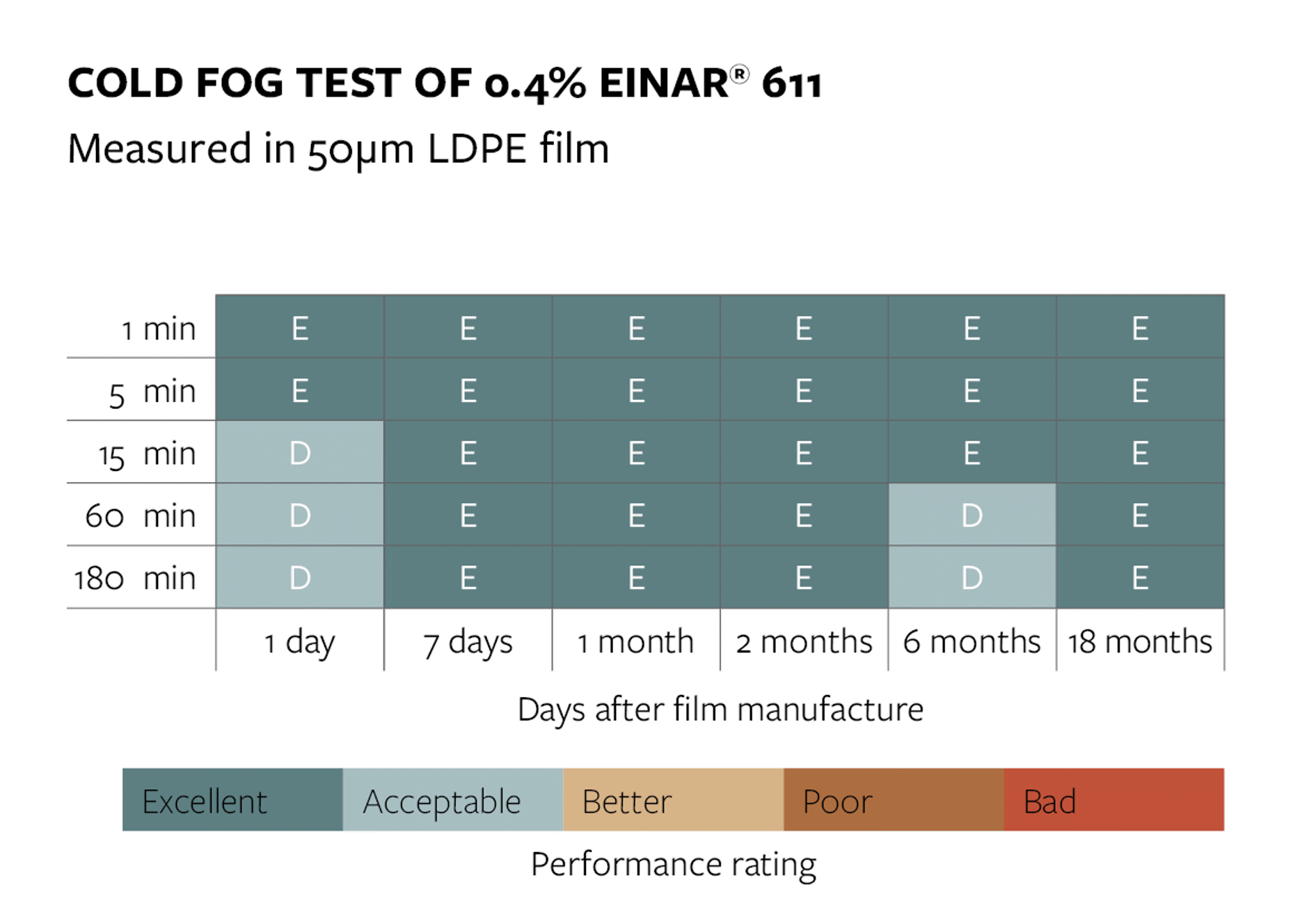

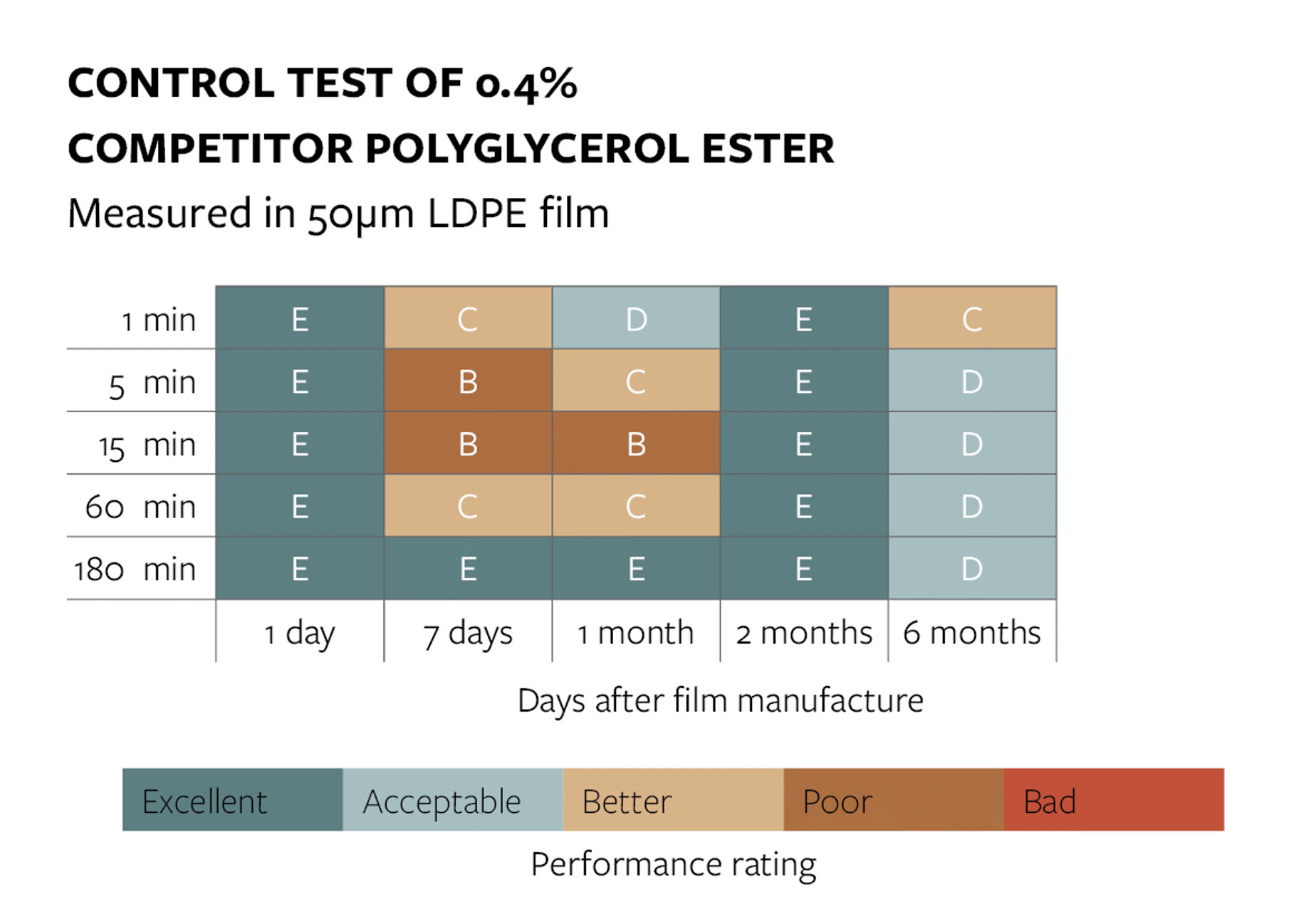

ANTI-FOG SOLUTIONS FOR PE AND PP

Supporting circularity

As packaging moves towards mono-material designs and thinner films to improve recyclability, achieving effective anti-static and anti-fog performance becomes more demanding. Einar® additives help masterbatch producers deliver solutions that meet these evolving requirements –while supporting resource efficiency and keeping packaged food fresh for a longer time.

This commitment to circularity reflects Palsgaard’s broader sustainability vision. Through our Heart Working Commitments, we integrate environmental responsibility into every aspect of our operations, ensuring that the solutions we offer today contribute to a more sustainable tomorrow.

Our ESG commitment

Sustainability is at the heart of Palsgaard’s business strategy. We take measurable action to protect people, reduce environmental impact, and promote ethical practices across the value chain.

These initiatives align with the UN Sustainable Development Goals and reflect our commitment to transparency and continuous improvement.

For full details, visit our ESG page.

Comprehensive technical support

Our sustainability efforts go hand in hand with technical excellence. At Palsgaard’s Polymer Innovation Centre in Denmark, we simulate real-world processing conditions to help masterbatch producers and converters optimise performance while meeting circularity and ESG goals. Producers are invited to request samples and benefit from expert guidance during qualification and implementation – ensuring that every solution delivers on both technical and sustainability promises.

FEATURE ARTICLE

FEATURE ARTICLE

VIDEO FEATURE

FEATURE ARTICLE

TECHNICAL ARTICLE

VIDEO FEATURE

TECHNICAL ARTICLE

WHITEPAPER