RESPONSIBILITY

Responsible Sourcing Programme

Our Responsible Sourcing Programme is managed from headquarters, where a central Procurement function sources most raw materials used.

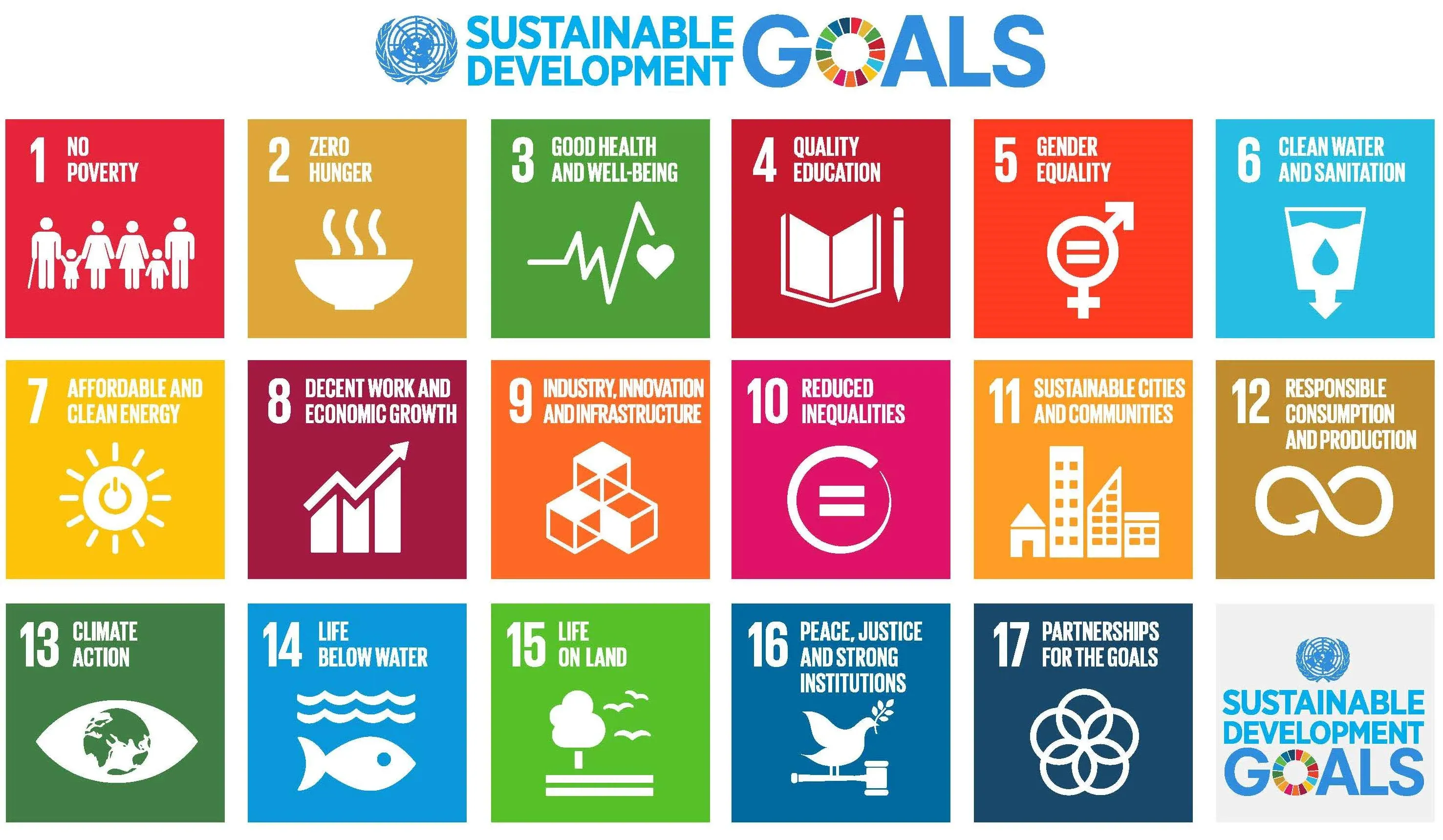

All suppliers must sign a Supplier Code of Conduct that includes a provision identifying Palsgaard as a signatory to the UNGC and answer a CSR supplier information sheet.

By signing the documents, suppliers warrant that they will conduct business pursuant to the UNGC’s 10 principles within four areas: Human Rights, Labour, Environment and Anti-Corruption.

86% of all suppliers have been accessed in our Responsible Sourcing Programme

Our raw materials are grown and therefore sourced from countries all over the world. This diverse mix of countries naturally comes with a mix of cultures and beliefs, especially when it comes to sustainability and fair labour conditions. The challenge is that not all of these countries prioritise these elements, which contrasts with Palsgaard's own ambitions and principles. The Responsible Sourcing Programme helps us to address some of these issues yet it is a challenge that we openly recognise.

While suppliers more than one link away are a challenge, we still set ambitious goals, express our attitudes and exploit every opportunity. For example, one supplier in India achieved an award for good corporate citizenship from the local chamber of commerce, partly as a result of Palsgaard’s encouragement. Overall, most suppliers are well on the way to improving sustainability, while the remainder requires further dialogue.

Palsgaard will collaborate with a supplier following an extensive evaluation covering specifications, food safety, CSR performance and compliance with EU legislation. A risk profile is created based on country of origin, production and location of harvest. Where relevant, a continuous improvement plan is made in collaboration with suppliers, to address sustainability.

We are scoping the inclusion of a Sedex evaluation into our Responsible Sourcing Programme in an effort to have an extended overview of our suppliers' performance on human rights.

Supplier management has long been an integral component of our quality assurance system and is a measurable KPI. Our Supplier Code of Conduct, Responsible Sourcing Programme and our corporate culture and ethics, dictate supplier due diligence and define the CSR requirements we set for suppliers and partners.

New suppliers sign a Supplier Code of Conduct that includes a provision identifying Palsgaard as a signatory to the UNGC and answer a CSR Supplier Information Sheet (SIS). The SIS is a point-based system that determines their sustainability status and is applied to suppliers within the top 85% of spending on raw materials and packaging. By signing the documents, suppliers warrant that they will conduct business pursuant to the UNGC’s 10 principles within four areas: Human Rights, Labour, Environment and Anti-corruption. Suppliers are reassessed at regular intervals. Additionally, a sub-contractor code of conduct has been implemented in Malaysia.

Supplier sustainability evaluations take place three times a year and are part of the overall Quality Management System evaluation.

RESPONSIBILITY

RESPONSIBILITY

RESPONSIBLE PRODUCTION

RESPONSIBLE PRODUCTS

RESPONSIBLE PRODUCTS

RESPONSIBLE COMPANY

RESPONSIBLE COMPANY

RESPONSIBLE COMPANY

RESPONSIBLE COMPANY

RESPONSIBILITY

RESPONSIBLE COMPANY